Engineers today are faced with a lot of responsibility when it comes to PCB design. As part of this responsibility, you are tasked with choosing the right electronic components to include in your designs. Component selection is more than just “does it do what I want it to do”, it involves a larger process of researching and choosing suitable parts, that are in stock, fit within the budget, can be easily implemented into your PCB design resulting in an end-product that will perform its intended operation.

Every circuit is different and therefore will require different components with different qualities to solve different problems. How do you go about choosing the most effective and efficient component to solve your circuitry needs? This is a decision that should not be taken lightly, as an improper selection of parts can end up costing you both time and money down the road. Below we have outlined several aspects to consider when choosing components for your next project, feel free to reach out to us on social media or in an email to give us your thoughts and continue the conversation.Things to consider when choosing a component for your board:

Electronic Specs

When it comes to component selection, electronic specs are arguably the most important aspect to consider. There are millions of similar electronic parts out on the market designed to perform specific functions within a circuit. The number of electronic components to choose from can be overwhelming. A good place to start is to consider what industry you are designing for, ex. military, medical, automotive, commercial? Products created for different industry sectors can be very distinct, although they perform similar functions. Military products are typically reproduced on a smaller scale but need to have robust features including the ability to withstand extreme conditions. Products for the automotive sector may need to have longer lifecycles in order to last in a car for 15-20 years. Electronics designed for the commercial sector tend to have a wide range of applications and can vary greatly from one to another.

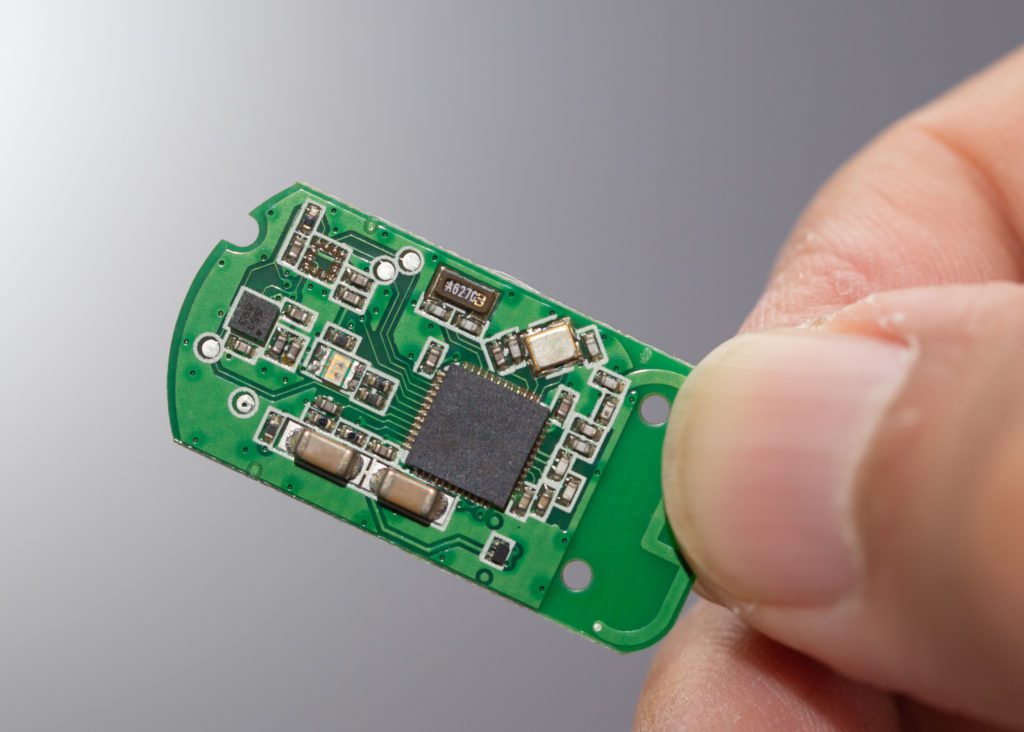

When researching electronic specs it is also important to keep in mind the different attributes associated with components. Many chip manufacturers and distributors offer similar components with the same functions but different package styles which may dictate what component you choose. Consider what is most important to your design. For example, are you concerned with power consumption or temperature? With the rise of small wearable electronics maybe your biggest concern is package size or weight. Whatever your concerns or design specifications are, there will still be several different components to choose from for every aspect from physical form, to mounting specs and even materials.

Compliance

It is hard to avoid the growing concern for environmental sustainability in today’s society. In the past materials used in the creation and manufacturing of components including lead, mercury, and cadmium, have had negative irreversible impacts on the environment. Over the past 10 years, as demand continues to increase for electronic products, key industry players have begun to focus on the environmental impacts of manufacturing certain components. As a result, government organizations such as the European Union, have implemented regulations restricting the use of certain materials in the manufacturing of electronic products at a global level. Understanding these concerns and their reach is a very important aspect to consider when choosing a PCB component for your board. If the chip has been created outside of the environmental stipulations required, there is a good chance that your product will be illegal to sell in certain countries.

One globally recognized environmental directive set forth in the electronics industry is RoHS (Restriction of Hazardous Substances). Developed by the European Union, RoHS was adopted to promote environmental and human safety. RoHS restricts the use of lead, mercury, cadmium, chromium (VI), PBBs, and PBDEs in electronics. If you happen to design a component that is not RoHS compliant, you will not be able to sell that product in certain countries including China, Turkey, countries in Europe, and even some states within the US. As you begin to filter out components in your research process based on functions and electronic specs you should also consider filtering based on compliance requirements for your target market as well.

Availability

More than just a procurement issue, availability and stock levels can have a huge impact on the success of your end-product. If you choose to include a component in your design and come to find out that there is a limited supply available on the market, you may be forced to re-design parts of your board to include components that are readily available. Alternatively, if you are designing for a prototype, you will want to ensure you can order smaller quantities of parts and get them quickly. During the research process, it is highly recommended that you create a list of alternate components and sources for your component choices in case you run into a situation where it becomes difficult to source a particular part.

Not only is it important to ensure the component you choose is currently available, it is equally important that the component will continue to be available in the future. Throughout your research, you should be checking to see if the component you are thinking about choosing is in a good spot in the product life-cycle. Selecting components that are near the end-of-life can be risky and result in regular product re-spins. Avoid using older components when possible, and opt for those that are newer to the market.

Pricing

With so many components to choose from, it may be difficult to know when to splurge and when to conserve. Although pricing might not be on at the top of your priority list, cost is important to those engineers who are working to produce a board within a certain budget. The last thing you want is to finish your design only to be told you need to re-engineer the board to reduce the BOM costs.

When you are in the research phase, compare components with the same or similar functions to see the difference in price. Some functions may be more important and therefore will require you to spend a little bit more, where others may be less vital to the circuit in which case you can go with a cheaper part. Another approach would be to compare pricing across different manufacturers or distributors. Additionally, if you plan on buying in bulk have a conversation with the manufacturers and see if they provide discounts for larger orders. Lastly, if you work in a company that regularly creates electronic products, look to implement a standardization initiative across the company requiring standard parts be used in several products, allowing the company to get bulk rates and making your component decision-making process much easier.

Libraries (Symbols, Footprints, and 3D models)

Once you have gone through the entire research phase and made a final decision on a part that meets all the pre-requisite requirements listed above you want to get to designing as quickly as possible. In order to design parts into your schematic and PCB layout, you will want accurate schematic symbol and a PCB footprints. Ideally, you can find these parts online because let’s be honest you did not become an engineer to spend hours re-creating schematic symbols and PCB footprints to add in your design.

With that in mind, you will want to check for pre-built data including schematic symbols, PCB footprints, and 3D models from a reliable source. How many times have you worked on a design where you get the symbol, footprint, and 3D model from three different sources—and of course they don’t match? If all the parts are sourced separately or built at different times, they may not be in sync which can lead to miscommunication and design errors. Poorly built parts will need to be corrected taking more time away from the overall PCB design.

Another aspect of reliability in component libraries to consider is if parts have been built to industry standard specs. IPC and ANSI are globally recognized standards that have been developed to ensure consistency across models in the electronic industry. These standards not only help to ensure a common set of rules for library creation but also provides common naming conventions and guidelines that can be used by you and your downstream design and manufacturing partners.

Part Search Made Easy

With everything you need to consider when choosing components for your design, time is of the essence. Part research and decision making should not take up the bulk of your time, ideally, all the above information is in once place.

Everything you need to know, all in one place.

Don’t stress Ultra Librarian has got you covered, providing access to all the information you need to make smart component decisions. In a single search engine, you can return information on electronic specs, compliance, availability, pricing, and download models for schematic symbols, PCB footprints, and 3D models. Shorten your design process by choosing parts for your next project through Ultra Librarian. Start Searching Now