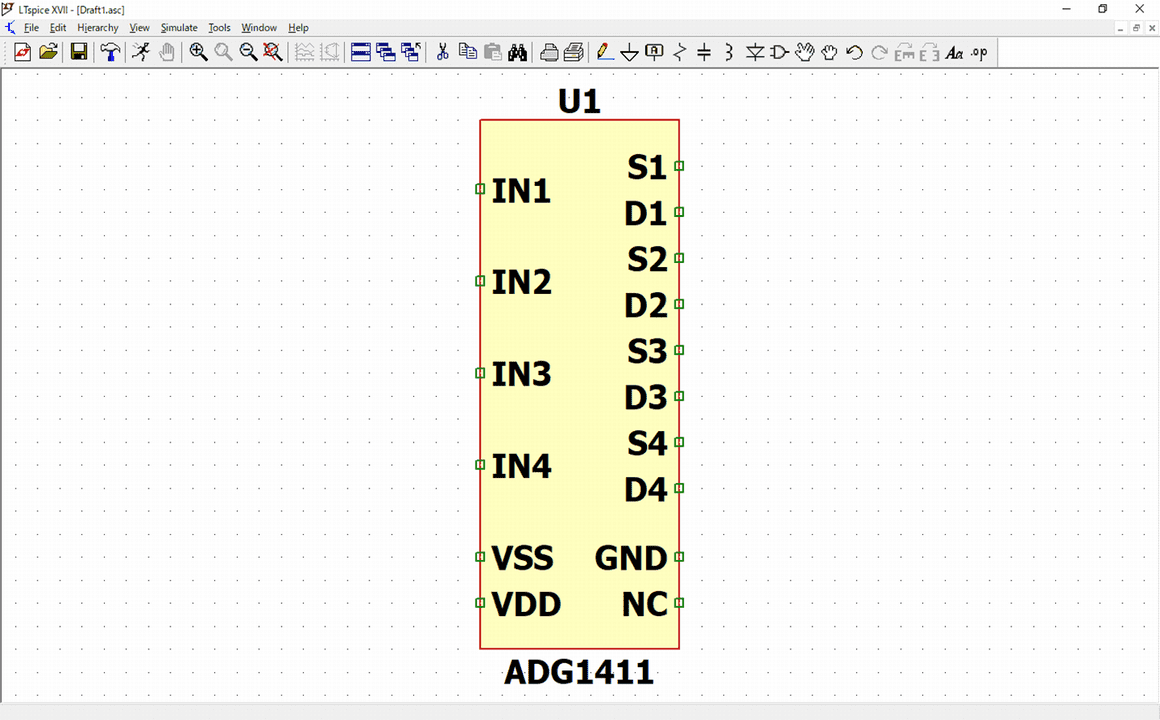

Creating a hardware start-up is perhaps one of the most challenging tasks an entrepreneur can take on, especially because a hardware start-up requires a vast amount of resources. These resources might go to creating electronic components, sourcing PCB footprints, or creating component schematics. Selecting the right component footprints for a hardware start-up can determine whether the start-up succeeds or fails. Since industry relies on quality components, it’s crucial for a start-up’s success to create superior components.

Why Is It Important for Hardware Start-Ups to Find Reliable PCB Component Footprints?

The electronics industry faces an insidious problem of counterfeit or low quality parts from disreputable suppliers. Security measures are available for hardware and software, but bad parts and unreliable PCB footprints can still make their way to well-meaning manufacturers. Hardware startups base everything on the quality of their components, so careful planning is essential at all stages of the production process. This includes making sure components comply with electronics standards, which many companies rely on as a measure of quality. If a PCB footprint does not conform to one or more international standards of electronics quality, this is a red flag signaling an illegitimate footprint.

Reliable PCB footprints can be sourced from a variety of places, at minimal cost to a start-up. The cost of a PCB footprint doesn’t guarantee quality, so a hardware start-up should not feel restricted to using free or low-cost footprints. Instead, hardware start-ups should choose their footprints and any associated libraries based on the adherence to standards, as well as the ability to verify conformance. Low quality PCB footprints may claim to follow international standards, and rely on a designer’s assumption they are reputable. It may not always be possible to verify every PCB footprint, particularly if it’s part of a library containing thousands or millions of models and schematic symbols. Legitimate PCB footprints should always be verifiable with a minimum of work, and designers should be wary if they must do extensive work to verify a footprint’s quality.

What Benefits Do Reliable PCB Component Footprints Offer Hardware Start-Ups?

Giving designers confidence in their designs is an important benefit of a reliable PCB component footprint. This confidence allows designers to tailor the design process to their start-up goals. Some start-ups focus on minimizing costs with their designs, while others focus on maximizing a design’s sustainability or prioritizing design flexibility. A hardware start-up often has to achieve multiple goals in component design, and reputable PCB component footprints make high quality designing much easier. High quality footprints also lead to finished products that are easier to test, have fewer defects in product runs, and a more streamlined design process.

Reliable PCB component footprints also allow designers an unparalleled amount of freedom with their designs. When designers don’t have to worry about basic component footprints being unreliable, they can use the footprints to create customized, complex designs with confidence. Extensive testing is always necessary with customized or complicated designs, but designers can better identify useful testing areas and lower the potential for defects if they know basic components already adhere to international standards. Customized components or complete electronics projects can be built in this way, trading costly exhaustive testing for efficient targeted testing.

Components and projects inevitably become obsolete over time, so reliable PCB component footprints also allow designers to make updates on previous versions of their designs. These updates can be anything from replacing a component with a more modern variant, or completely reworking a project to take advantage of new models and concepts. PCB component footprints help electronic manufacturers feel secure in adopting and evolving new technologies. This allows manufacturers to use those technologies as they see fit, without disregarding the knowledge and usefulness gained from previous designs.

What Are the Consequences of Failing to Find Reliable PCB Component Footprint Libraries?

The most direct consequence of using unreliable PCB footprints is the creation of low quality parts. In order to build trust among clients, a hardware start-up should strive for the highest standards of quality possible. Since start-ups don’t have the same resources as larger companies, a single bad production run could cause irreparable harm to a start-up’s reputation. Reliable PCB component footprints can essentially eliminate this potentially devastating problem. All companies have an occasional bad production run, but if a start-up can quickly replace defective parts with high quality parts— backed by PCB component footprints—the company may be able to avoid any lasting damage.

Hardware start-ups should also be aware of the far-reaching consequences of producing low quality components. For example, if a start-up has a contract to supply parts for medical devices, but didn’t use reliable PCB component footprints to create those parts, the failure of those parts could impact medical care, endangering lives. While defects of any kind can be dangerous in the right conditions, this doesn’t exempt hardware start-ups from implementing strict quality control, starting with their PCB footprints.

Ultra Librarian provides PCB component footprints for hardware start-ups of any size or business niche. Our partnerships with worldwide distributors ensure high quality components for every project. Working with Ultra Librarian takes the guesswork out of preparing for your next great device, and puts your ideas on the road to success. Register today for free!