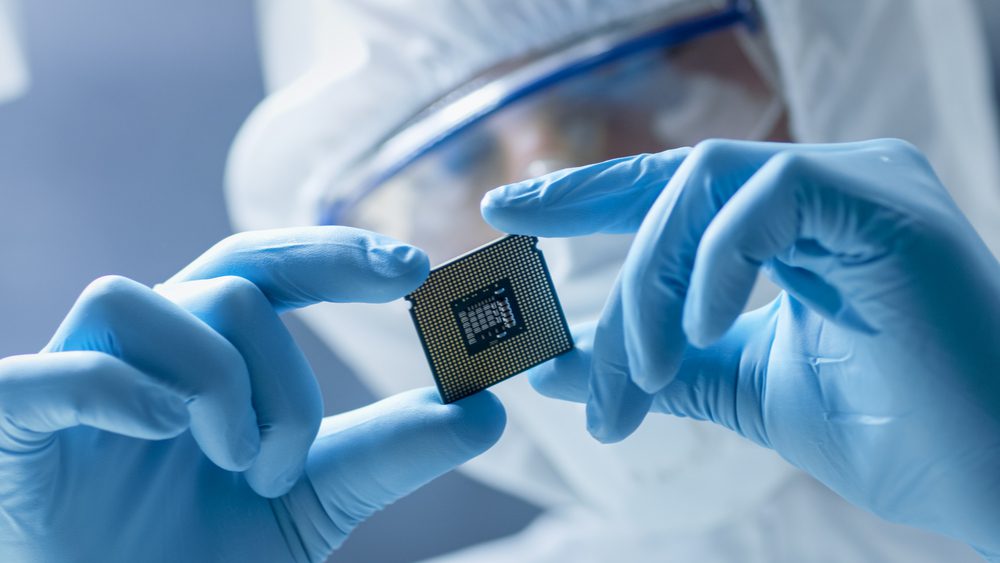

The COVID-19 pandemic has impacted the electronics industry in unprecedented ways, causing supply problems, manufacturing delays, and major business losses across the world. Every manufacturing company has had to re-evaluate its supply chain and business model to stay afloat. Given these challenges, it is easy to think component suppliers might be unreliable during the pandemic. However, this dire outlook doesn’t reflect reality—there are many ways designers can choose and maintain reliable relationships with component suppliers even during these difficult times.

Are Component Suppliers Reliable During COVID-19?

Component suppliers aren’t expecting a recovery in the electronics industry for some time. Many suppliers and manufacturers started preparing for the prospect of a long-term downturn very early in the pandemic. Although it may have cost them short-term gains, the data-driven approach of these suppliers made them among the most reliable as the pandemic continued. Data-driven analysis of component sourcing is not a new idea, but it has become ever more important in the currently uncertain climate. Component suppliers who acted quickly to analyze data and prepare for the worst-case scenario are those handling supply now. At the beginning of the pandemic, many component suppliers didn’t have a good grasp on the effect of international supply chains, especially since before the virus, experts were predicting 2020 would be a year of significant industry growth.

The reliability of component suppliers in the COVID-19 world hinges on increased collaboration between suppliers and designers. The best time to source new components is at the beginning of the design phase. Designers are getting accustomed to long lead times, which allows for more planning time. However, extended delays can mean pricing changes or stock shortages that make a design untenable. Planning for this possibility can help designers meet their deadlines, and help suppliers to continue to deliver useful components. Designers who insist on using a specific component, rather than an equally workable alternative, could miss out on working with an otherwise reliable component supplier.

Can Component Suppliers Flourish During COVID-19?

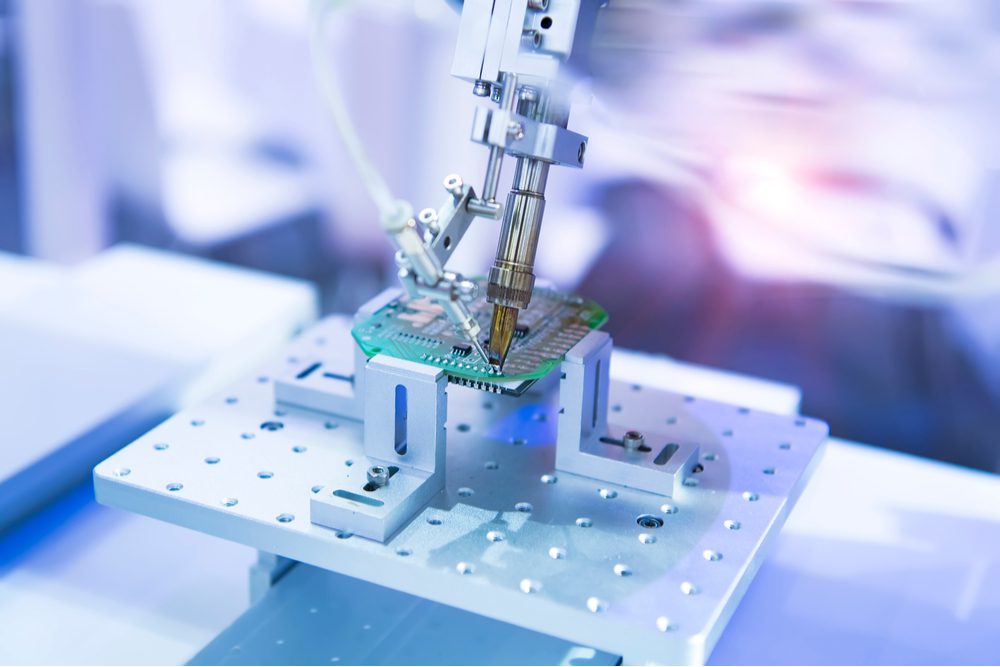

Although it might seem counter-intuitive, component suppliers can find new markets during COVID-19. They can do this by tracking important changes in the industry and the requirements of technology that reflects those changes. Gathering requirements to select the right components has always been necessary for electronics design, but COVID-19 has inspired some component suppliers to apply their components in new ways. Some companies have completely redesigned their manufacturing processes, focusing only on high-demand components, such as those for the medical industry. While this restricts the flexibility of a component supplier and may make it difficult to fulfill other orders, the strategy also creates a constant revenue stream and positive publicity for the supplier.

If a component supplier changes its focus to high-demand components, this can be a jarring change for a designer. This is especially true if the supplier no longer supplies the components they once did. Designers can stay ahead of this by keeping up with current information about electronics supply chain forecasts. If a designer can find a secondary component supplier who has also been monitoring forecasts, that’s a good indicator the supplier will be reliable, and might even flourish under adversity. The more information a designer can find about a component supplier, the better. Tried-and-true resources like component search engines and detailed datasheet readings can give designers crucial information about a component supplier’s ability to be flexible.

How Should Designers Handle Component Suppliers During COVID-19?

Good relationships with component suppliers are vital to preventing and mitigating vital component shortages. COVID-19 makes it more difficult for manufacturers and component suppliers to set up mutually acceptable agreements. This is because both sides have a significant amount at stake for their own interests. Manufacturers must understand component suppliers have obligations to other clients, while component suppliers must remember to ensure enough materials for their clients. Both sides must also be ready to change their agreements if necessary without sabotaging their relationships or business interests. Designers must be more willing than ever to be flexible and make sacrifices to maintain relationships with suppliers. This is called proactive positioning.

Manufacturers and component suppliers must respond, not react, to each other. This means collaboration on many levels—sharing data, doing research, and forging business connections. A component supplier who is willing to collaborate, be flexible, and keep their clients informed of any changes in capabilities is an ideal partner for a manufacturing company that wants to succeed during difficult times.

Ultra Librarian connects electronics designers with reputable component suppliers, ensuring quality designs and peace of mind. Working with Ultra Librarian takes the guesswork out of preparing for your next great device, and puts your ideas on the road to success. Register today for free.