Connectors carry signals and information between boards and components within a larger system. The M12 connector and the related M12/M8 connector system have become favorites among industrial engineers, who often look for rugged connector and cabling systems.

M12 connectors are common general-purpose connectors found on many cable types to support protocols like Process Field Bus (Profibus). However, there is no single M12 connector; there are many possible M12 connector pinouts that can be used in different systems.

M12 connectors are commonly used to interface between PLCs, electromechanical systems, and other electrical systems on the factory floor. When you’re designing around this connector system, you’ll need an M12 connector pinout to interface with signal ports on the Rx/Tx sides of a connection.

In this article, we will delve a little deeper into M12 connectors—what they are and where they should be used.

What are M12 Connectors?

The M12 connector is a circular keyed connector with a 12-mm locking thread. They provide a rugged, flexible option for connecting a wide variety of equipment. The M12 connector was originally designed for use in corrosive environments where reliability is key, although M12 connectors can also be used in higher-end factory environments requiring high data transfer rates. Primary uses of this connector are in industrial automation, including actuators, industrial Ethernet, sensors, Profibus, and Fieldbus.

Unlike some other connector types, such as USB, the M12 connector is meant to be non-removable. M12 connectors can be securely attached by soldering, securing with vertical through holes, or right-angle connectors. They are built to withstand environmental stresses and to be waterproof, making them ideal for heavy-duty applications. Their shells are stainless steel or plated with brass and nickel to withstand rust and corrosion. In addition, they function at a wide range of temperatures, from -40 to 85 °C. This covers conditions ranging from high temperatures in many factories and extends into temperatures well below freezing. In general, M12 connectors for flexible use have lower temperature tolerances than those connectors that are rigid once installed.

M12 Connector Codes

M12 connectors are coded based on whether they need to carry data or power.

Data Applications

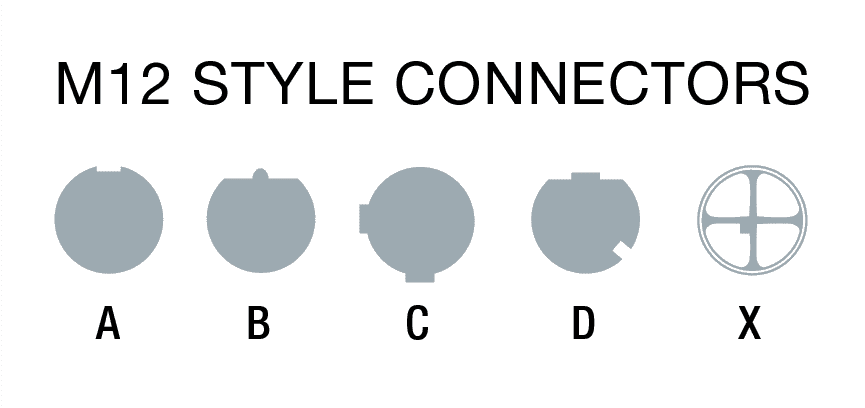

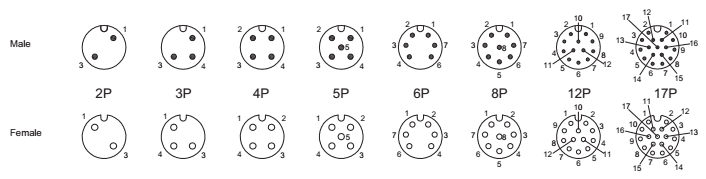

For data applications, there are 5 major types of M12 connectors coded with the labels A, B, C, D, or X. These connectors are available with 2, 3, 4, 5, 6, 8, 12, or 17 pins, depending on the number of signals, type of signals, type of interface involved in the connection, and the connector code. Note that each coded connector has its own key format, and different connector styles have different possible numbers of pins. The common key styles for the 5 major M12 connector codes are shown below.

Power Applications

There are also 5 additional M12 connector codes for AC power, DC power, and general-purpose use in different protocols. These are S-coded M12 connectors for AC power, which will eventually replace C-coded power parts. T-coded M12 connectors are designed for DC power and will eventually replace the use of A-coded connectors for supplying DC power. Finally, the K-coded M12 connector is under development for AC power, while the L-coded connector is used for DC power in Profinet buses. The table below summarizes the various M12 connector codes and their applications.

|

Connector code |

Applications |

| A | Sensors, DC power, gigabit Ethernet |

| B | Profibus connections |

| C | AC power |

| D | Up to 100 Mbit Ethernet (Standard TIA 568-B) |

| X | Up to 10 Gbit Ethernet (Standard TIA-568-C.2) |

| S and K | AC power |

| T and L | DC power |

| P | Various uses |

M12 Connector Pinout

The specific M12 connector pinout for different coding types only depends on the number of pins. The image below shows the pin arrangement for an A-coded connector, but similar pinouts are shown for other connector codes. For example, a C-coded M12 connector can have 6 pins, while B-coded has 5 pins, and D-coded has 4 pins. The top key position shown below also matches the top key position for other connector styles. In addition, the pin styles shown below are used across connector styles.

Selecting the Right M12 Connector

If you need to select an M12 connector, it’s best to simply follow the recommendations on your equipment datasheet. Look at the absolute maximum power and temperature ratings your equipment will run at and select a cable with a suitable safety factor above these values. When you need to search by specification, it helps to use a great electronics search engine to find your components and connectors.

How are M12 Connectors Related to M8 Connectors?

M8 connectors are specifically used in industrial automated systems, linking sensors, actuators, and switches. M12 connectors can fill these roles, but they are also useful in measurement, food and beverage, and robotics applications. This expanded use is partially because M12 connectors can remain functional while submerged, and M8 connectors cannot.

The technology for both connector types began in 1982 with a ⅞ inch connector that could be secured with a spinning nut. M12 connectors came first, followed by M8 connectors in 1989. Their names don’t reflect a series of incremental advancements, as one might assume based on the numbers. They are named for the thread on their coupling nuts—12 mm for the M12 and 8 mm for the M8. From this perspective, the connectors reflect the decades-long trend toward making technology smaller. However, it also emphasizes the fact that making technology smaller doesn’t necessarily make larger technologies obsolete, and different varieties of similar technologies can be of great use.

M8 and M12 connectors are vital to compact communication systems. M12 connectors and cables require conformance with more standards than M8 variants since they have broader applications. The flexibility of M12 connectors even gives them the ability to connect directly to PCB headers, if necessary. Connecting to a PCB header, however, could make the underlying board vulnerable to physical or chemical damage without appropriate protective measures.

Whether you need an M8 or M12 connector pinout, Ultra Librarian provides datasheets and 3D models for a range of commercially available connectors. Designers can also access prices, distributor inventory, and technical specs for a range of electronic components and connectors. You will have access to verified CAD models directly from manufacturers, which can be imported into popular ECAD applications. You will also have access to sourcing information from worldwide distributors.

Working with Ultra Librarian takes the guesswork out of preparing your next product and puts your ideas on the road to success. Register today for free.