If you look at almost every development board or evaluation kit, you’ll see lines of pin headers along the edge of these boards. Pin headers are great for interfacing with a range of sensors or other boards and for applying jumpers when needed. Production-grade boards that will be deployed in a harsh environment need a more reliable connector with a rugged cable assembly. Instead of doing everything custom, there are connector options for everything from power units to high-speed digital systems.

The Harwin M80 series of connectors is one popular connector solution for power supply units, embedded systems, automotive solutions, and much more. Unlike a typical pin header for a ribbon connector, you can get high bandwidth with a mechanically reliable connection, without the need for a custom cable assembly. Before you pick out one of these connectors for your system, take a look at the Harwin M80 connector datasheet.

Harwin Datamate (M80 and M83) Connectors

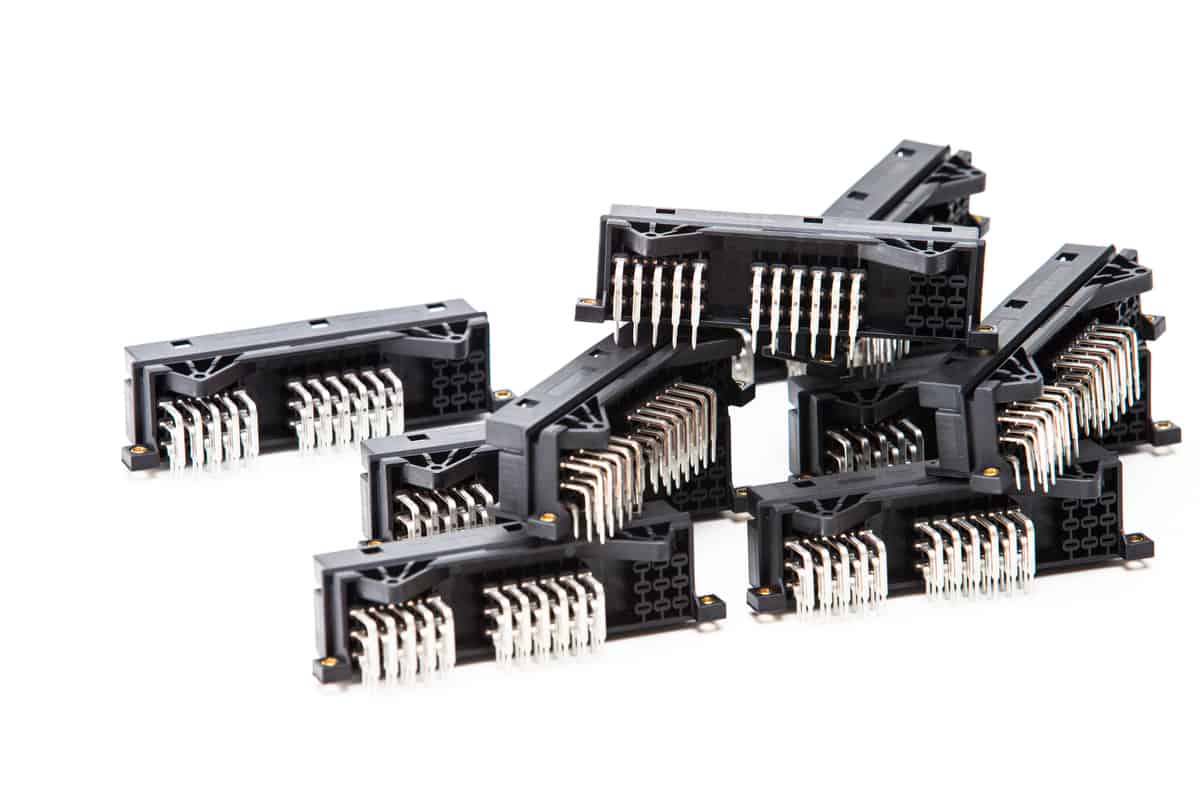

More commonly known as M80 connectors, the Datamate series by Harwin is meant to be a rugged solution for signal and power connections. These connectors are available as surface-mount or through-hole connectors for cable assemblies or they can be used as board-to-board connectors. Compared to pin headers, these connectors provide much greater mechanical strength and are available as shrouded/keyed connectors with a locking mechanism.

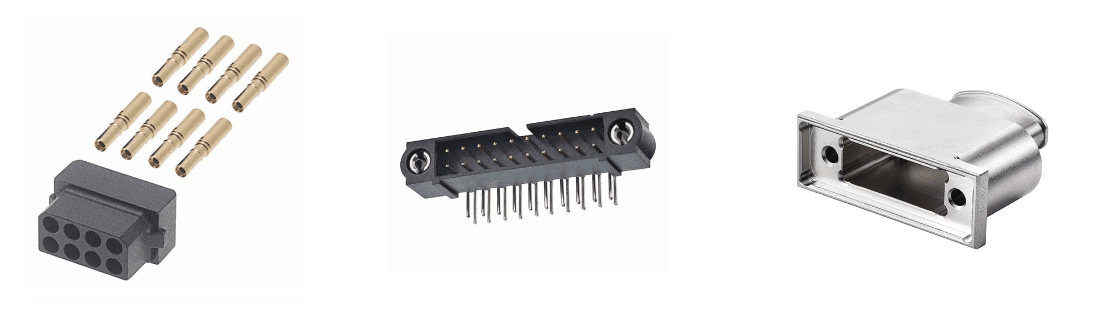

M80 Connector Components

Harwin’s line of M80 connectors are available in two form factors:

- Cable connectors: These connectors can be mounted against an enclosure or left hanging as part of a rugged cable assembly. M80 cable connector kits use crimped contacts that slide through the connector shroud for a mechanically rugged connection.

- Mountable PCB connectors: These connectors resemble a standard pin header, but the female portion of the connector is much more substantial than a standard ribbon connector.

Finally, the M80 Datamate line also includes metal shrouds for cable connectors and mountable PCB connectors, offering an option for additional shielding that fits with either connector style. This type of modular connector and cable assembly is an easy-to-use option for a range of applications where pin headers won’t meet mechanical requirements. Some application areas for Harwin M80 connectors include automotive modules (e.g., ECUs), high current embedded power supplies, high power RF connections, and high data rate connections for embedded systems.

Components in the Harwin M80 Datamate connector series

M80 vs. M83 Connector

The other type of Harwin Datamate connector is the M83 connector. These connectors are available in 6 standard sizes and up to 96 positions (32 x 3 rows), whereas the M80 connectors are a more modular solution with more options. The electrical specifications of the M80 and M83 connectors are identical, so an M83 connector can be used as an alternative component when the desired form factor for an M80 is unavailable.

Understanding the Harwin M80 Connector Datasheet

Like many connectors that are part of a product line or series, there is no single Harwin M80 connector datasheet. The technical data for Harwin Datamate connectors can be found in the Datamate Product Guide. This document is comprehensive and is a good proxy for a typical datasheet.

Aside from important points like the pinout and connector dimensions, the Harwin M80 connector guide includes the following important specifications:

- Current limit: These connectors offer very high current limits; individual contacts can support 3 A maximum current, and high pin-count connectors are rated as high as 80 A total current. For power delivery applications at high current, it’s best to opt for more pins in the connector with current split in parallel to stay under the 80 A maximum.

- Cable type and row count: M80 Datamate connectors can support standard AWG wiring or coaxial wiring. Connectors are available with up to 3 rows of pins.

- Frequency limit: M80 connectors for coaxial connections are rated as reliable for frequencies up to 6 GHz, making them useful for a wide range of RF power applications. Although not stated explicitly, other important electrical ratings can be assumed stable up to this limit.

- Impedance and VSWR: The impedance rating of 50 Ω is given as the input impedance and output impedance seen at the ends of the connectors. VSWR quantifies the mismatch between the cable impedance and the end connector impedances. The formula for VSWR in M80 Datamate connectors is 1.05 + (0.04 x Frequency) GHz max.

- Voltage ratings: The operating voltage for M80 connectors is rated at 180 V AC up to 1000 V AC (RMS).

- Contact resistance: The M80 connectors and their pins have a very low contact resistance of 6 mΩ maximum.

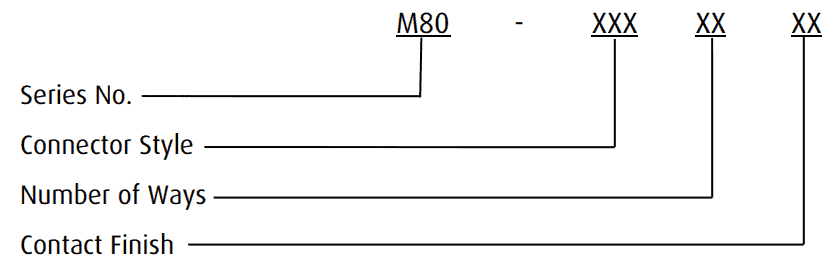

When you’re looking for an M80 connector, pay attention to the structure of the part number. These part numbers have a specific format, as shown in the following image.

Harwin M80 Datamate connector part number format

Because there are so many different types of M80 connectors, it’s important to use a quality electronics search engine to find parts. You’ll need more than sourcing information, you’ll also need footprints for PCB-mountable connectors and 3D STEP models for use in your CAD tools. If you want to build a new design with M80 Datamate connectors, you can find the components and CAD models you need with an electronic parts search engine.

The next time you need to find a Harwin M80 connector datasheet, sourcing information, or CAD models, try using the electronics search engine features in Ultra Librarian. In addition to component data, you’ll have access to verified component models that can be imported into popular ECAD applications. You’ll also have access to sourcing information from worldwide distributors.

Working with Ultra Librarian sets up your team for success to ensure any design is going through production and validation with accurate models and footprints to work from. Register today for free.