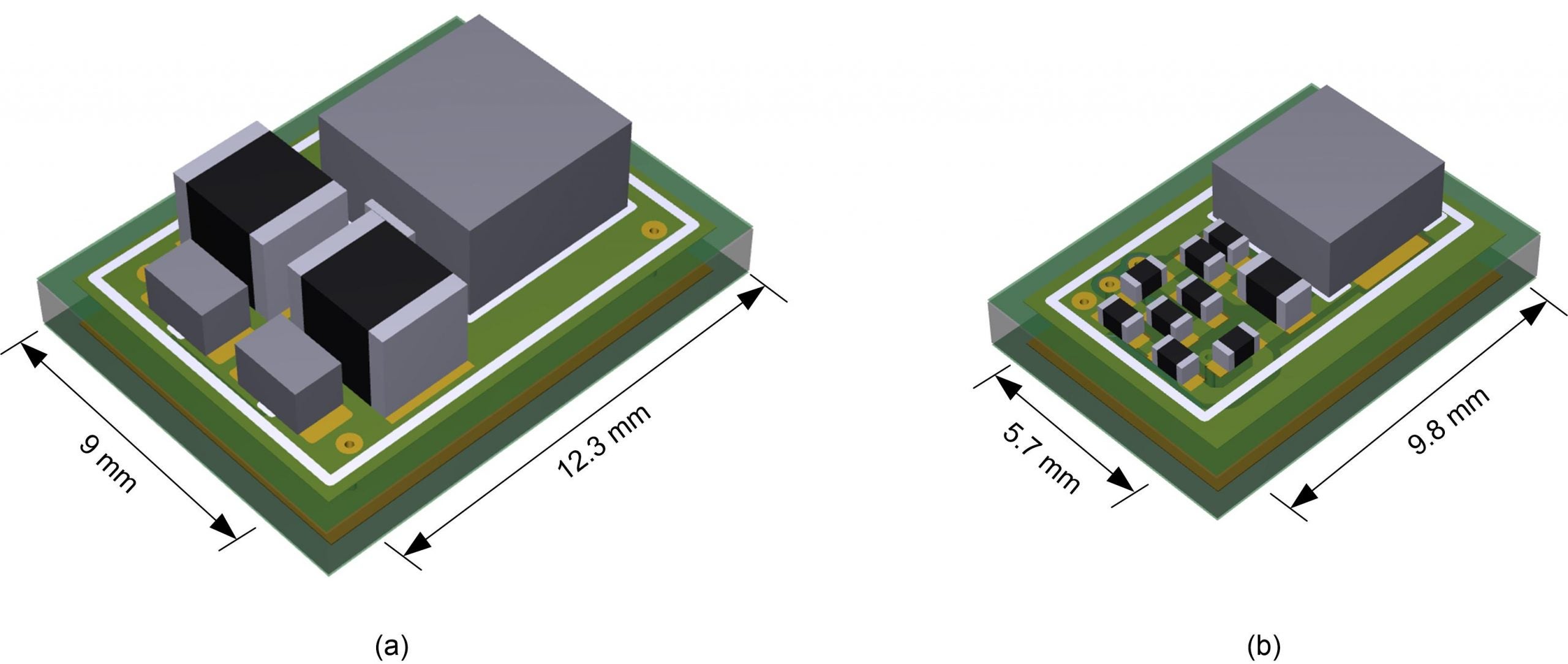

When working on low-electromagnetic interface (EMI) applications design engineers are required to reduce the EMI of their designs and shrink the solution size. There are a few methods a design engineer can take in order to accomplish this like Front-end passive filtering, however this method can be at odds with increasing the power density of low-EMI designs, especially with the effects of increased switching speeds on the overall EMI signature. Passive filters can be bulky and can take up as much as 30% of the total volume of the power solution, so there still needs to be a viable solution for minimizing the volume of the EMI filter while simultaneously increasing power density.

An active EMI filter senses any noise or ripple from the DC/DC switching regulator and injects a signal 180º out of phase to cancel the noise, effectively minimizing conducted emissions and allowing for a 50% reduction in passive EMI filter size.

LM25149

42-V synchronous buck DC/DC controller with ultra-low IQ & intergraded active EMI filter

LM25149-Q1

42-V automotive synchronous buck DC/DC controller with ultra-low IQ & integrated active EMI filter

The LM25149-Q1 42-V automotive buck controller is the industry’s first switching regulator with an active EMI filter integrated into the IC.

EMI Training Series

Texas Instruments has designed an in-depth training series on Designing a low EMI power supply, recognizing the challenges design engineers face when balancing size and EMI emissions.

Additional Resources

Texas Instruments (TI) has an in-depth analysis of how to reduce EMI and shrink power-supply size with an integrated active EMI filter in their recent technical article.