If you’re a new PCB designer, you’ll probably see a lot of printed circuit board terminology flying around, and it isn’t always clear what these terms mean. Engineering courses often lack a focus on PCB design in favor of a broader focus on systems design and semiconductors. These areas are important, but circuit boards are the fabric that links all these areas together, so it is important to understand basic terminology.

We’ve compiled some printed circuit board terminology for new designers below. Hopefully, understanding some of these basic terms will help you communicate with your colleagues as well as better understand the printed electronics design and manufacturing processes. We’ll look at printed circuit board terminology in three areas:

- The terminology used to describe the physical structure of a PCB

- The terminology used in ECAD software

- Manufacturing terminology

Printed Circuit Board Terminology

Some key printed circuit board terms focus on describing the physical structure of a PCB. These terms are also referenced in design and manufacturing, so it’s important to learn these first.

Layers: All circuit boards are constructed in layers, and the layers are pressed together to form a stackup. Each layer includes etched copper, which forms the conductors on the surface of each layer.

Copper pour: Areas of a PCB that are filled in with large regions of copper. These regions may be oddly-shaped.

Traces and transmission lines: These terms are used interchangeably, particularly for advanced high speed PCBs.

Signal vs. plane layer: A signal layer is intended to only carry electrical signals, but it could also have copper polygons that provide ground or power. Plane layers are intended to be complete planes without any signals.

Vias: These are small drilled holes in a PCB that allow a trace to move between two layers.

Components: Refers to any part that is placed on a PCB, including basic components like resistors, connectors, integrated circuits, and much more. Components can mount by being soldered to the surface (SMD components) or with leads that are soldered into copper holes (through-hole components) on the circuit board.

Pads and holes: Both of these are used to mount components to the circuit board and are used as a location to apply solder.

Silkscreen: This is the text and logos printed on the surface of a PCB. This contains information about component outlines, company logos or part numbers, reference designators, or any other information needed for fabrication, assembly, and regular use.

Reference designators: These tell the designer and assembler which components are placed in different locations on the circuit board. Each component has a reference designator, and these designators can be found in the design files in your ECAD software.

Soldermask: This is the top-most layer in a PCB that gives the circuit board its characteristic color (usually green).

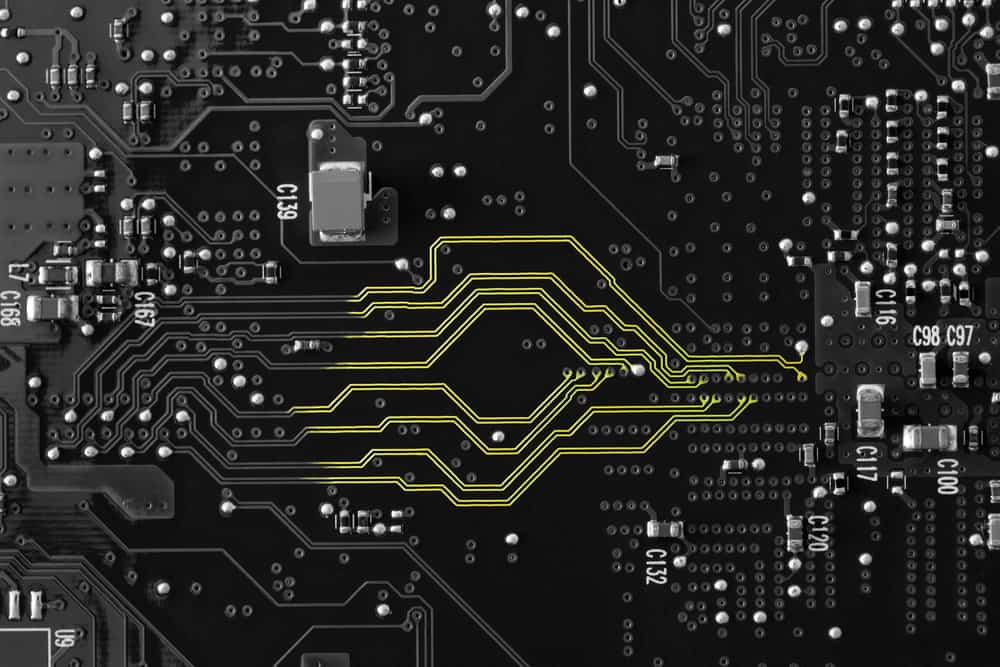

A PCB layout can get quite complicated and sometimes it’s hard to see all these features. The image below shows a CAD drawing of a PCB layout, and some of these features are indicated.

CAD drawing of a PCB layout

PCB Design Terminology

Different ECAD applications will use slightly different terminology, but there are some terms that are commonly used in all PCB design applications:

Schematics: These are like the blueprints for your design. These documents show how electrical connections are made between components as well as connections to power and ground.

PCB layout: This is a physical representation of your PCB, just like the CAD drawing shown above.

Nets: Any electrical connection between terminals on a circuit board is known as a net. This defines the starting points and endpoints for an electrical connection in a schematic (e.g., bus connection or point-to-point connection), which will then be connected with traces on a PCB layout.

Schematic symbol: This is usually a box with some pins that is meant to represent the available electrical connections on a component. Each pin represents a physical electrical connection that can be made on a real component.

PCB Footprint: A PCB footprint, or simply footprint, shows the arrangement of pads or holes on a component, which will then be used to make electrical connections with traces in a PCB layout.

STEP file: A 3D model format used in mechanical modeling programs and advanced PCB design applications.

Example CAD data for an Infineon RFH5004TRPBF MOSFET

Libraries: A PCB library contains component models, each of which contains a symbol, footprint, simulation models, and a STEP model.

SPICE: A general circuit simulation package that is used in integrated circuit design and PCB design. Designers need to have simulation models for their components in order to run SPICE simulations.

PCB Manufacturing Terminology

Finally, there are some basic PCB manufacturing terms that designers may encounter.

PCB fabrication: Refers to the construction of the bare board from layered materials. This encompasses all portions of the bare-board construction process.

PCB assembly: Refers to the process of placing and mounting components to a bare PCB.

FR-4: This is not a specific material, but rather a class of materials used in circuit board design and fabrication. This acronym indicates the laminate material is fire resistant up to NEMA Class 4.

Gerber files, ODB++ files: These files are generated from the PCB layout and are used to generate photoplotter stencils, which are then used to etch bare copper-clad PCBs during fabrication.

Netlist: Defines all electrical connections on a PCB in a human-readable format. This file is used to verify electrical connections during manufacturability checks and to define test criteria for automated testing equipment.

Pick-and-place: A type of automated assembly equipment used to grab and place components on a bare board before soldering.

Soldering: Refers to three possible processes used to secure components to a PCB: hand soldering, selective soldering, and wave soldering.

Selective soldering machine

The terms above are just some of the important printed circuit board terminology that designers should know. An electronics search engine like Ultra Librarian can help you stay up to date on new developments in the industry and find components you need for your design. Ultra Librarian understands the importance of testing electronic components, lifecycle management, and providing data to users. You’ll have access to CAD models for your components and verified 3D models that can be imported into popular ECAD applications. You’ll also have access to sourcing information from worldwide distributors.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.