The transition from internal combustion engines (ICEs) to electrical vehicles (EVs) is happening swiftly. Within the last few years several countries have set targets to either reduce the sales of ICEs or wipe out their usage:

| Country | Goal for transition to EVs |

| United Kingdom | Banning ICEs by 2040 |

| France | End sales of ICEs by 2040 |

| India | EVs for sale only by 2030 |

| Norway | Only zero-emission vehicles by 2025 |

The EV industry holds so much promise but there is one main concern among its adopters: charging the batteries. EVs can only drive so far before needing their battery recharged, and while this is comparable to needing to fuel up an ICE after some distance, it only takes a few minutes to fill your tank while charging an EV can take hours. Although creating higher capacity batteries for EVs is the main challenge, the industry is shifting its attention to EV chargers and how to make them cheaper yet more efficient.

We may see an increase in the number of EVs without onboard chargers. Currently, when an EV is plugged in to charge, it will receive AC current. The OBC converts it into DC so the energy can be stored in the battery. Removing the OBC could potentially make EVs more affordable but also requires portable (in-home) DC chargers. These portable DC chargers must be kept small in size and be reliable in the long-term.

The Evolution of EV Charging:

Advancement in Topologies:

Multilevel topologies have been introduced to increase power and decrease charging times in these DC chargers. While the control scheme is more complex when compared to the two-level, it is significantly smaller and lighter thanks to the decreased size of the passives. Being able to switch between three or more voltages means multilevel topologies have significantly lower switching and conduction losses, which creates greater efficiency and higher power levels. The switching voltages are also half the voltage of a two-level inverter, which creates better EMI and makes EVs with 800v battery technology easier to support.

Smaller passives, lower switching voltages, and improved EMI makes multilevel topology the preferred architecture for DC charging stations.

Bidirectional Charging:

EV chargers are switching from unidirectional charging to bidirectional, so it can be charged and discharged by a charging station. Currently, most OBCs do not support bidirectional charging. A portable DC charger can give EV owners access to this charging method, which is even more important for customers who live in areas with time-of-use tariffs where energy prices differ between day and night. Bidirectional chargers can also help stabilize the grid and act as a backup power source during peak times.

Portable DC Chargers:

Utilizing multilevel topologies and bidirectional charging allow for a DC charger to be offered at different prices and power levels for the same EV and battery size, so customers can pick a charger that suits their needs.

The increased efficiency of these portable chargers is enabled by wide band gap technology like the GaN FET LMG3522R030-Q1, which has faster switching frequencies and lower switching losses. On top of this faster and more efficient charging, the smaller size and weight with multilevel operation makes it exceptionally convenient for a portable charger.

A real-time micro controller with high-frequency pulse-width modulation enables higher switching frequencies of a GaN FET for lower switching losses and integration of protection for the power switch. The Configurable Logic Block (CLB) of the C2000 TMS320F280049 can be used to implement hardware protection that customers in the past used FPGAs for to help save cost and improve reliability.

The shunt-based current sensing that is incorporated into the charger increases the accuracy, linearity and magnetic immunity. The AMC3302 has integrated power supply which makes for a small solution that can easily be used in the power control loop.

Where to Get Started

Ready to engage in the future of the electric vehicle industry? Our partners at Texas Instruments have created a curated selection of reference designs that are built to help you take advantage of these new technologies and continue to innovate in the rapidly evolving infrastructure of EV charging:

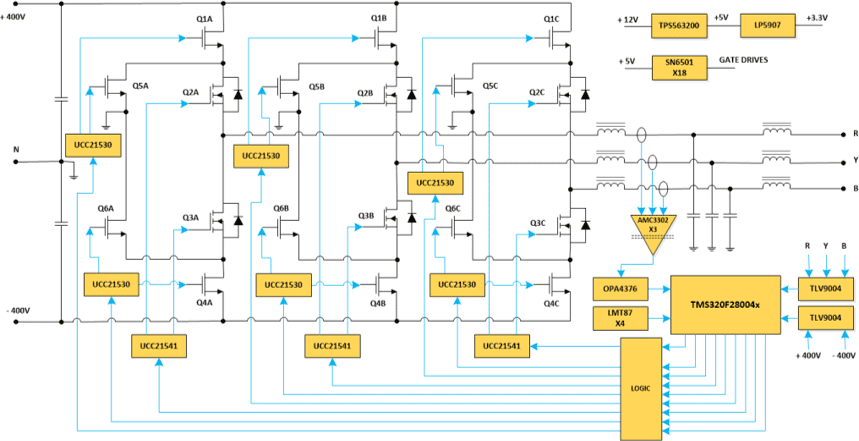

A Bidirectional Charging Power Stage: TIDA-010210

The TIDA-010210 from TI is a 6.6kW three-level, three-phase, SiC/GaN based ANPC inverter power stage. The use of fast-switching power devices makes it possible to switch at a higher frequency of 100 kHz, reducing the size of magnetics for the filter and increasing the power density of the power stage. The multilevel topology allows the use of 600-V rated power devices at higher DC bus voltages of up to 1000 V. The lower switching voltage stress reduces switching losses resulting in a peak efficiency of 98.5%. This design is modular in construction, making it configurable to work with SiC or GaN power devices with the same filter stage.

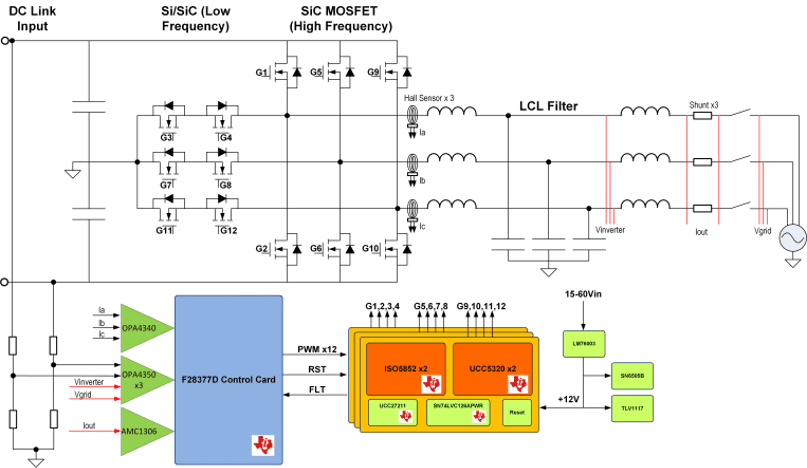

A Bidirectional Three-Phase, Three-Level Inverter: TIDA-01606

The TIDA-01606 from TI is a three-level three-phase SiC based DC:AC T-type inverter stage. Higher switching frequency of 50KHz reduces the size of magnetics for the filter design and enables higher power density. The use of SiC MOSFETs with switching loss ensures higher DC bus voltages of up to 1000V and lower switching losses with a peak efficiency of 99 percent. This design is configurable to work as a two-level or three-level inverter.

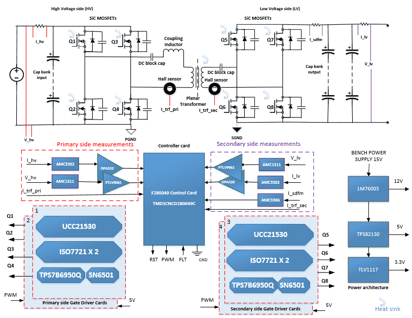

A Bidirectional, Dual Active Bridge for Level 3 EV Charging Stations: TIDA-010054

In the TIDA-010054 from TI, the dual active bridge (DAB) topology offers advantages like soft-switching commutations, a decreased number of devices and high efficiency. The design is beneficial where power density, cost, weight, galvanic isolation, high voltage conversion ratio and reliability are critical factors, making it ideal for EV charging stations and energy storage applications. Modularity and symmetrical structure in DAB allow for stacking converters to achieve high power throughput and facilitate a bidirectional mode of operation to support battery charging and discharging applications.

More resources for fast DC chargers

Looking for even more resources from Texas Instruments? Explore their solutions for fast DC chargers here: https://www.ti.com/solution/dc-charging-pile-station.

Once you find the parts you need Ultra Librarian is ready to supply you with the necessary TI CAD models to get your design jump started and off the ground quickly.