Electronic sensor

One of the essential devices used in electronic systems is the sensor. This is evidenced by the many types that exist. For example, electronic sensors measure temperature, humidity, vibration, pressure, strain, fluid flow, and position. Sensors also vary from elementary components to highly advanced systems. The most implemented are position sensors, which may be linear, rotary, contacting, and non-contacting.

Two very common non-contacting sensors are capacitive and inductive sensors. These components are often called switches as they are typically used to identify whether a condition or state is true or false. For example, if the default condition of the target is true and the sensor is normally closed (NC), then a state change from true to false will cause the sensor to open–this is often accompanied by a visual indication, such as a LED turning on. For PBCA design, you may be confronted with the choice of whether to use a capacitive vs. inductive sensor. Making the best choice depends upon your understanding of each of these discrete components.

Using Capacitive Sensors

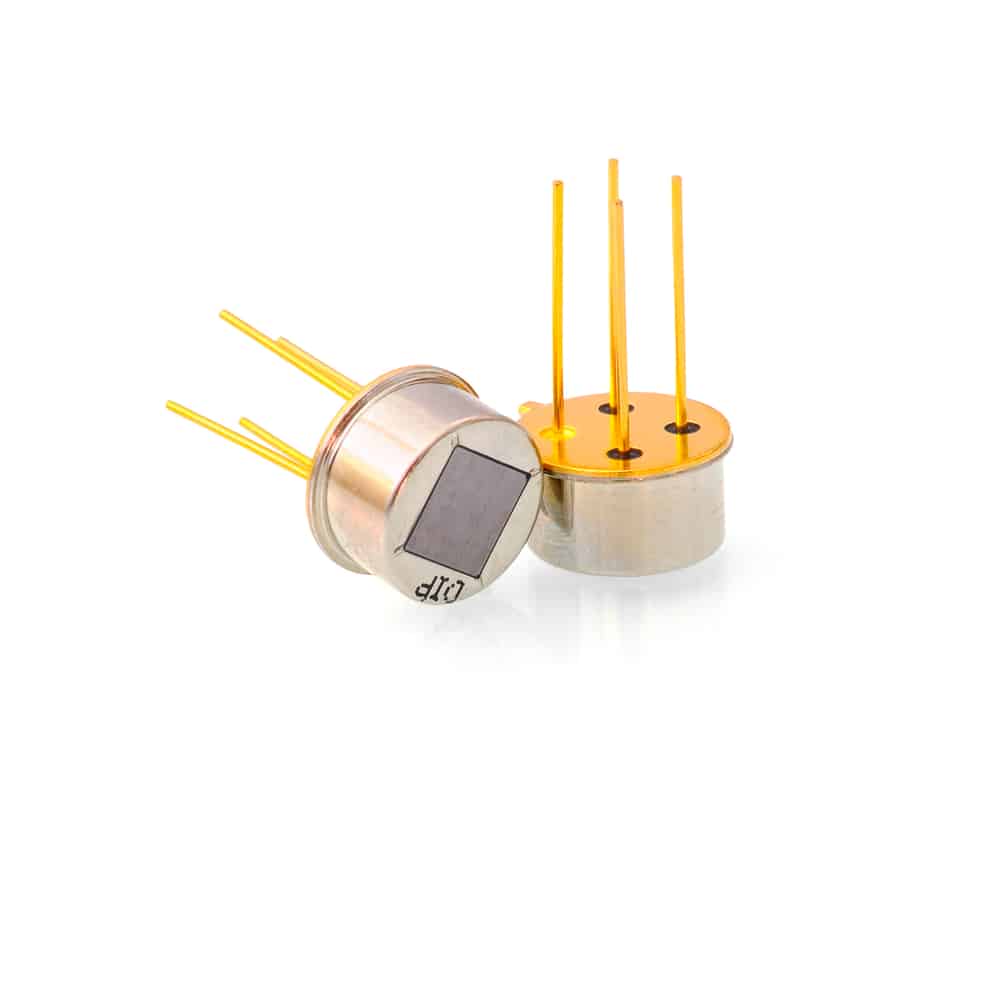

Capacitive sensor

The figure above shows an example of a capacitive sensor. The advantages of using this type of sensor are listed below.

Advantages

- Low cost

- Low power

- Can sense different types of materials (e.g., plastic, metal, skin, liquid)

- Contactless

- Wearfree

Capacitive sensors are often found in industrial environments as they can be utilized to detect, identify or measure different types of objects and substances.

Applications

- Proximity sensing

- Material analysis

- Liquid level detection

- Human presence

These components may be active or passive and have a relatively simple construction and operation.

Capacitive sensor diagram. From RealPars.

Capacitive sensors typically consist of four major parts or sections, as listed below.

Capacitive sensor sections

- Cable

The sensor’s cable is used for both power and signaling. Often the cable is attached to a PCBA power supply with voltage levels in the range of 12V to 36V. The cable also contains two wires over which the output signal is sent. For example, if the sensor is detecting the proximity of an object, the output will only exist when the object is within range.

- Indicator

The indicator is primarily for external notification and functions similar to the output signal–ON for detected objects and OFF when no object is in range.

- Body

Inside the body is where the primary sensor circuitry is located. This includes two plates–a capacitor–, an oscillator, detector, and output circuitry for transmission to the external load.

- Face

The face is where the sensing or detection occurs. When no object is present, the dielectric between the plates is equal to that of air–approximately 1.00059 at sea level. This value changes when an object–especially a metallic object–enters the sensor’s detection range, and the sensor produces an output signifying detection.

An alternative to capacitive sensing is the use of an inductive sensor.

Inductive Sensors and Their Applications

Inductive sensor switch

Inductive sensors, an example of which is shown in the figure above, are used to detect metallic objects–except iron-based. These components come in a variety of configurations; however, they usually have the following characteristics.

Characteristics of Inductive Sensors

Advantages

- Durable

- Used in harsh environments

- Long operational life

- Fast switching rate

- AC or DC

- Shielded or unshielded

- Contactless

Applications

- Detect metallic objects

- Human presence

As shown above, inductive sensors are durable enough to be used in harsh environments. They are also available shielded or unshielded and easy to mount.

There is little difference in the overall construction of capacitive vs inductive sensors, as both have a cable connection, body, face, and indicator. However, inductive sensor operation is based on two functions.

Operation of Induction Sensor

- Magnetic Field Detection

Inductive sensors generate a magnetic field that changes with the introduction of a magnetic object.

- Current Sensing

The flow of current creates the sensor’s magnetic field through a coil in its body. A change in the magnetic field due to an object in the range of the device alters the current flow resulting in an output signal and an indication.

Using an inductive sensor instead of a capacitive sensor can be a difficult decision. However, by examining these two options for similar criteria, you can make the best choice for your specific design.

Capacitive vs Inductive Sensor: Making the Best Choice

Inductive sensors, as indicated above, have advantages which make them a good choice for many sensing or detecting applications, especially in harsh environments. However, capacitive sensors are versatile and may be used to detect different types of objects or even fluids. When deciding which to utilize, it can be quite helpful to compare these devices for like attributes, as in the table below.

| SELECTING CAPACITIVE VS INDUCTIVE SENSOR | ||

| Sensor Attributes | Capacitive | Inductive |

| Non-contact | ✔ | ✔ |

| AC | ✔ | ✔ |

| DC | ✔ | ✔ |

| Active | ✔ | ✔ |

| Passive | ✔ | ✔ |

| Fluid flow detection | ✔ | |

| Metallic object detection | ✔ | ✔ |

| Fast switching | ✔ | |

| Material analysis | ✔ | |

| Range | ✔ | |

| Durability | ✔ | |

| Harsh environment usage | ✔ | |

| Low power | ✔ | |

| Low cost | ✔ | |

As shown in the table above, distinguishing between capacitive vs inductive sensors is not an easy task. Yet, there are specific attributes for which each is a better choice. For example, capacitive sensors can be used to detect non-metallic objects and even fluid flow levels. By contrast, inductive sensing is largely limited to non-ferrous metallic objects. Inductive sensors can be used in harsh environments, have fast switching rates, and longer operational lifetimes than their capacitive counterparts. Both sensors can be operated with AC or DC and be active or passive, but capacitive sensors if they are applicable provide a lower power and cost sensing option.

Fortunately, both sensor types have been around and are well used in industry. Therefore, making the best selection also includes selecting the best online component source for accurate data and information source.

If you’re looking for CAD models for common components, Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.