Adhering to the right PCB standards is imperative when quality and safety are of utmost importance. However, it is often a challenge for companies trying to mark global footprints to bridge the gap between different standards. When it comes to the US, comparing ANSI vs IEC standards is a common debate amongst designers.

Understanding ANSI

ANSI (American National Standard Institute) acts as an administrator-cum-coordinator for the United States voluntary standardization system. ANSI is not a government agency- it’s a private non-profit organization working since 1918.

ANSI works in close collaboration with 270 Standards Developing Organizations (SDOs). These SDOs make standards, and ANSI provides processes to develop standards. Each recommended process is open, transparent, and consensus-based. ANSI represents and serves a diverse group of companies, organizations, and professionals worldwide.

Its role with policymakers is a public-private partnership. The US government is the most active participant in the standard-setting process. However, the government relies on private-sector mechanisms in its regulations.

The best part of the US standardization system is that, unlike many other economies, it offers a bottom-up approach- standard users drive the standardization activity, not the standard bodies.

Currently, there are 240+ ANSI-accredited standard developers (ASDs). Only ASDs can submit standards for approval as American National Standard (ANS). All ANS are subjected to a neutral third-party routine audit by ANSI.

Standards development and conformity assessment do go hand in hand. Once an ANSI standard is accepted and becomes an ANS, it has the potential to become the international standard.

Irrespective of ANSI vs IEC standards, it is worth knowing that ANSI is a US member of ISO as well as a US member of the IEC via ANSI’s US National Committee. ANSI has launched a service sector initiative. Under this initiative, ANSI focuses on new sub-sector areas such as unmanned vehicle systems or mobile devices that need new or enhanced standards.

Understanding IEC

IEC (International Electrotechnical Commission) is a global organization that prepares electrical and electronics technology. IEC was founded in London in 1906. IEC is open to volunteers from every possible level, such as industries, governments, developing countries as well as academia. Thousands of chosen experts from these levels form technical committees (TC), and each TC forms one or more sub-committees (SC).

For example, the IEC TC 17 represents the technical committee for high-voltage switchgear and controlgear. It has two SCs- SC 17A and SC 17C, representing sub-committees for switching devices and assemblies, respectively. TCs submit their scope of work and area of activity to the IEC Standardization Management Board (SMB) for approval.

IEC has Conformity Assessment Boards (CABs) to manage and supervise its conformity assessment activities. Further peer assessment ensures that CABs comply with:

- ISO general terms and definitions relating to conformity assessment (ISO/IEC 17000)

- IEC CA system rules

Conformity assessment (CA) refers to a set of processes to demonstrate that a product, system, service, or management meets the requirement of a standard. Thus, the assessment is important to suppliers, consumers, and regulators as it offers the necessary proof of a product’s safety, performance, and reliability.

A company can get in contact with the IEC CA system in any country to get a product certified. An IEC certification helps companies penetrate more markets faster at a low cost. As a result, consumers avail of safer products at a lower price. Thus, an IEC certification is a win-win situation for both manufacturers and consumers.

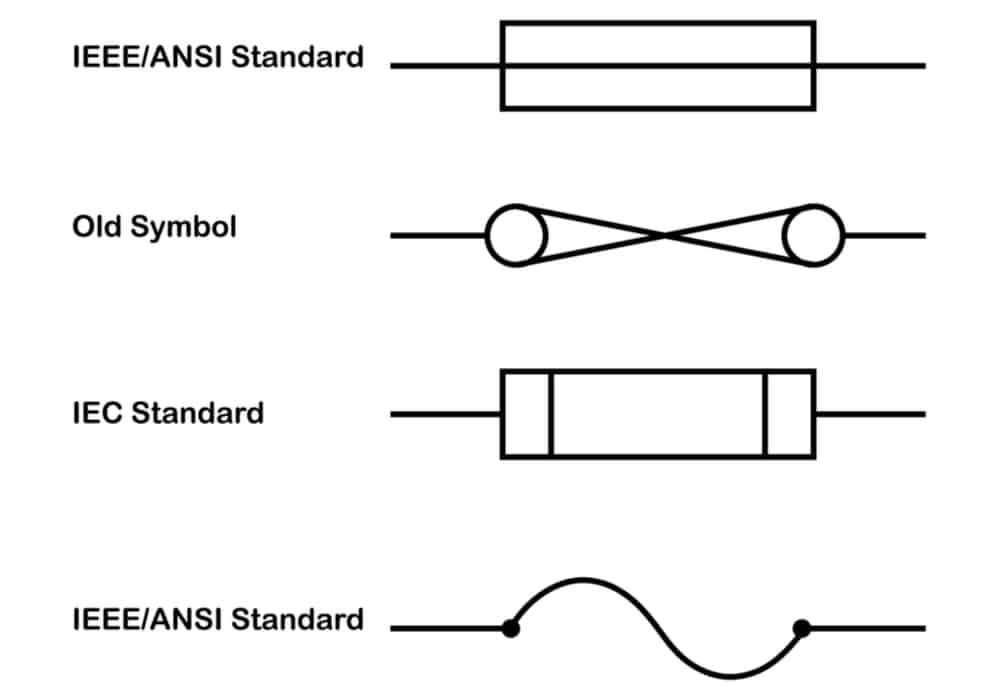

ANSI vs IEC Standards

While comparing ANSI vs IEC standards, it is easy to acknowledge that ANSI is a design-based standard, whereas IEC is inclined towards the functional approach of a product. The reason is simple. ANSI standards are highly sought-after in North America and selected other regions.

It is likely that products standing tall on ANSI standards may not perform well in environments outside North America. IEC standards, however, are globally accepted. There exists minor differences in the approach to defining certain terms by both standards. This fact can be easily acknowledged by looking at the definitions of short circuit current and transient recovery voltages from the lens of both standards. Thus, there began a harmonizing process by an agreement on a joint IEC – IEEE development project in 2008 to simplify such standards. As a result, most of the standards are in the transition phase. And comparing ANSI vs IEC standards is key.

Complying with the relevant standard can influence your PCB design success or failure. In this regard, it is also imperative to procure components in compliance with the standards for different applications.

Ultra Librarian features a huge online library to quickly look for any component along with footprints, technical data, and ECAD/MCAD models- all in one place. The search tool helps you find not only the primary component but also its ideal replacements and reliable sourcing information to strengthen your supply chain.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.