Following component library best practices and employing accurate manufacturer-verified CAD models are keys to PCB design optimization.

Regardless of PCB type, an electronic circuit board is a creation that originates from a list of performance goals or ideas. Developing these inspirations into an actual product is a complex path that includes design, manufacturing, and testing.

Throughout the development process, well-defined steps are performed with the aid of EDA tools, fabrication and assembly equipment, and electronic devices for measuring and analyzing parameters. The best process stages employ guidelines to maximize quality, minimize process time, and ensure reliability. Beginning with accurate, manufacturer-verified CAD models and following component library best practices, you can optimize your design’s operation and your board’s development.

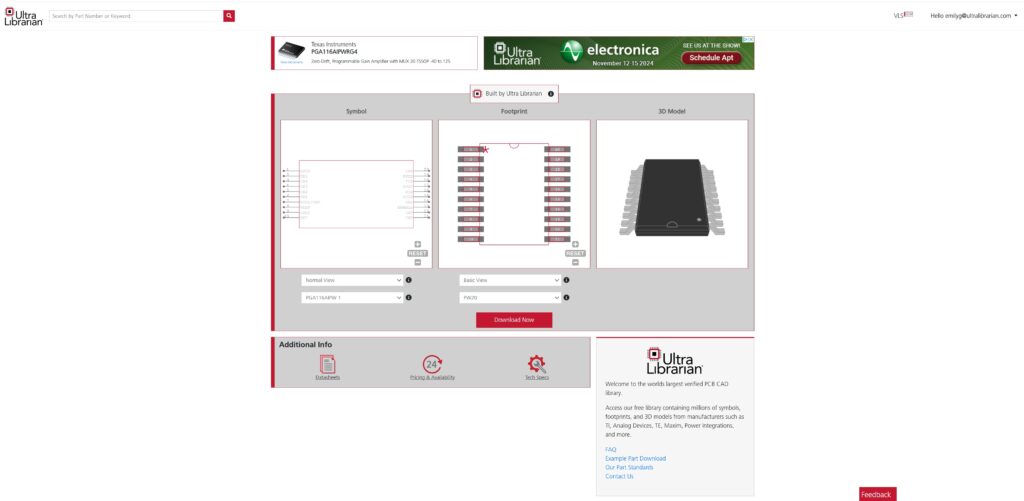

10 Component Library Best Practices

During PCBA design, following best practices for PCB layout or improving signal integrity, like minimizing EMI and EMC, is common. However, it is just as important to incorporate component library best practices, as listed below.

COMPONENT LIBRARY BEST PRACTICES | |

Component Library Practice | Why It’s Important |

Use standard symbol formats. | ✔ This will ensure your schematic is readable by everyone in the development chain. |

Employ manufacturer-defined footprints.

| ✔ Manufacturers will follow the IPC 7351 standard when creating part footprints. |

Use industry-standard CAD model formats. | ✔ Promotes efficiency for ECAD/MCAD integration. |

Include both 2D and 3D CAD models, if available. | ✔ This makes your design more application agnostic for ECAD/MCAD integration. |

Ensure your footprints match the MPN. | ✔ Helps avoid manufacturing problems due to BOM errors. |

Include specifications like dimensions, pinout, reference indicator location, etc.

| ✔ CMs rely on identifiers to ensure that footprints and landing patterns are correct, component placement and orientation are accurate, and spacing standards are followed. |

Ensure component data and information is current. | ✔ Outdated information can leave you with component availability problems that cost you time and money. |

Include alternative/equivalent components.

| ✔ This makes your development more resilient to supply chain disruptions. |

Include links to datasheets and other important design support documents. | ✔ Component datasheets contain important information that may be used at each stage of development. |

Avoid creating parts from scratch. | ✔ Errors in footprint creation translate into manufacturing issues that can halt or delay board builds and increase development costs. |

As the list above clearly indicates, several component best practices should be followed to support and aid the stages of PCBA development. For example, using standard and broadly accepted formats is essential. Doing so broadens the number of CMs you can partner with for your PCBA manufacturing services and supports efficient ECAD-MCAD for cases, enclosures, and system installation. Incorporating these best practices can be a challenge. Fortunately, there are options for implementing them.

Best Component Library Attributes

Your library should exhibit the following attributes to best meet the challenge of following the component library best practices defined above and optimize the circuit board development process:

Best Component Library Attributes | |

Resilience | Should be resistant to various changes to the supply chain, such as component obsolescence, reduced manufacturer production, long turnaround times, or other issues that may halt development and production. |

Volume | Access to the most needed components and alternatives while protecting against counterfeits and inferior parts. |

Scalable | Your component must grow and evolve with you to continually meet your design needs. |