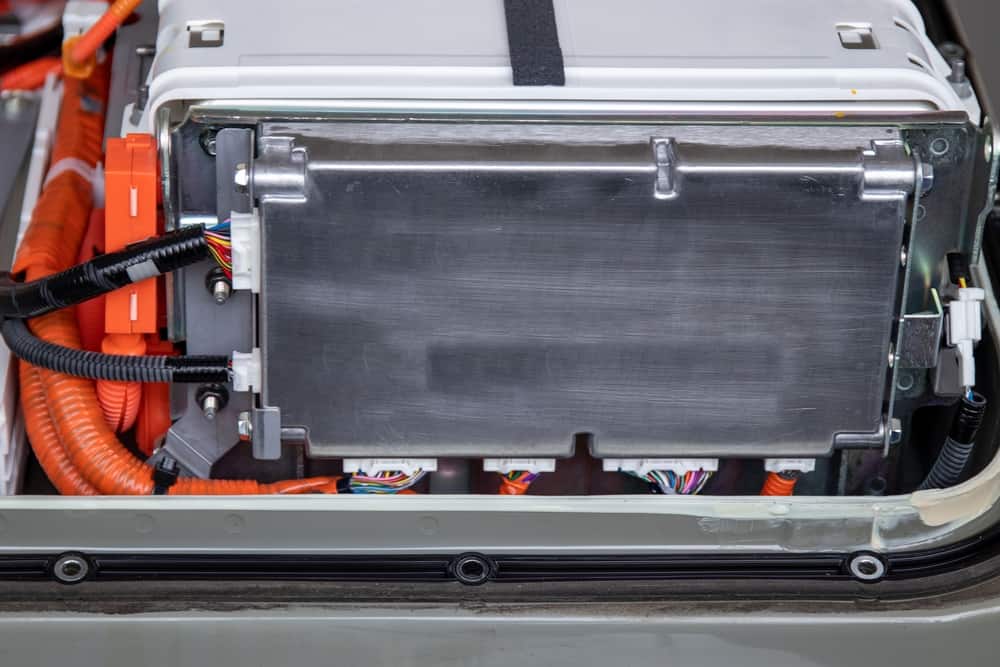

An EV battery management system

The amount of greenhouse gas emissions (GHG) continues to rise. In many countries; such as the USA, the largest contribution to GHG emissions comes from transportation. Fortunately, the trend is less growth due in large part to ambitious efforts like the Fit for 55 policies of the European Union. However, transitioning to alternative energy vehicles by individuals is ultimately based on performance.

Electric vehicles; including battery electric vehicles (BEVs), hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and fuel-cell electric vehicles (FCEVs), have attained a level of parity with combustion-engine automobiles. This achievement is based on technological improvements in battery storage capacities and EV system elements. However, the battery management system for electric vehicles is the critical electronic circuit board that ensures efficient and safe operation.

Battery Management Systems for Electric Vehicles

For all EVs, the battery management system (BMS) is responsible for controlling the power distribution network (PDN), an example of which is shown below.

EV power distribution network. Image from [1].

The PDN above illustrates how electric energy is utilized throughout the EV. Important PDN elements include:

Electric Vehicle PDN Elements

- Battery Charger

- HV Battery

- Bi-directional Converter

- DC-DC Converter

- Inverter

- Electric Motor

The BMS, which is often referred to as the energy management system or EMS, is the device that ensures the EV electrical network successfully addresses all power-related issues.

Power Management Challenges for EVs

In contrast to combustion engine transportation systems, EV operation and performance is completely dependent upon how well the BMS mitigates or eliminates electrical system challenges, which are listed below.

|

BATTERY MANAGEMENT SYSTEM FOR ELECTRIC VEHICLE CHALLENGES |

|

|

Challenge |

Requirement |

|

Power Distribution |

Ensuring all electrical system elements have the correct level of voltages and currents for operation |

|

Minimization of the amount of power used by helping to ensure system elements are operating within recommended ranges |

|

|

Thermal Issues |

Monitoring the electrical system for thermal violations and initiating mitigating action(s) when required |

|

System Safety |

Instigating and controlling the operation of safety equipment in response to electrical parameters overages/underages that threaten safe system operation |

|

Data and Analytics |

Collecting and disseminating system metrics and statistics to enable system oversight, support administrative functions , etc |

When developing battery management system PCBAs for electric vehicles, it is imperative that meeting the above requirements is a primary goal of the design process.

Best Practices for EV BMS Circuit Board Design

Understanding the purpose of a battery management system for EVs—and the performance and operational objectives for the PDN it will monitor and control—are essential for designing a PCBA that satisfies these requirements. Incorporating these and other important guidelines, as listed below, will aid you in developing circuit boards that achieve your BMS functionality and performance goals.

|

Battery Management System for EV Design Guidelines

|

As the list above indicates, your choices for which components and CAD models to use and where to source parts from are important to the quality of your BMS for EV design process and product.

If you’re looking for CAD models for common components or important information on how to best design PCBs for battery management systems for electric vehicles, Ultra Librarian helps by compiling sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.

References:

- Sankarkumar, RS, Natarajan, R. Energy management techniques and topologies suitable for hybrid energy storage system powered electric vehicles: An overview. Int Trans Electr Energ Syst. 2021; 31:e12819. https://doi.org/10.1002/2050-7038.12819.