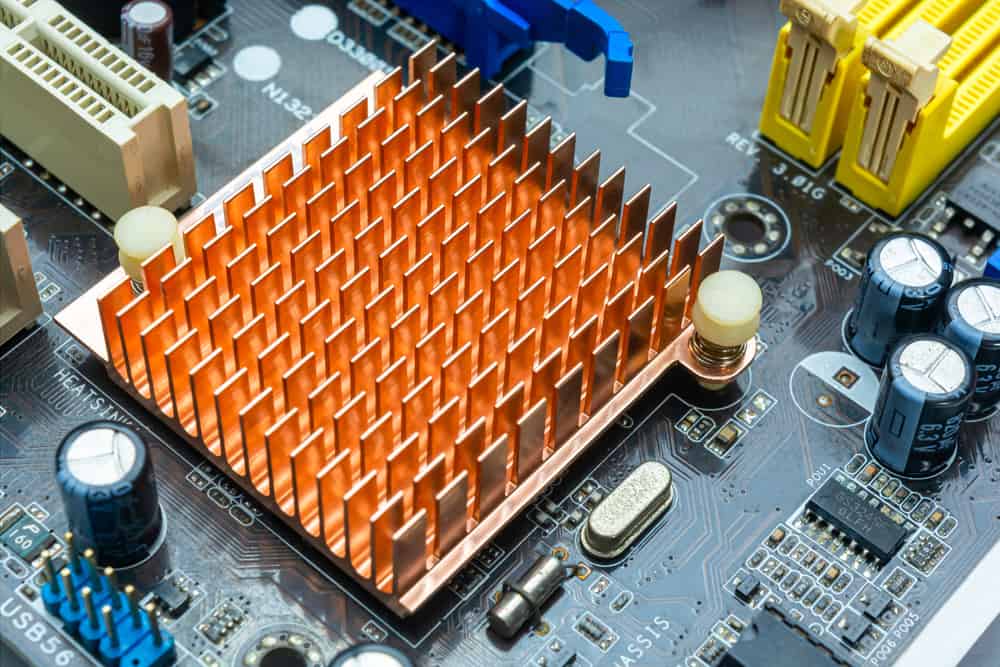

Good thermal management is a part of good EMI design guidelines

Ask any RF engineer or circuit board designer about their most challenging task, and you’re likely to receive a unanimous answer: minimizing noise or electromagnetic interference (EMI). Addressing this issue is undeniably the most difficult aspect of their work. Nevertheless, it is crucial to tackle EMI head-on due to its significant impact on the signal integrity (SI) of your board. Ensuring reliable operation and acceptable performance necessitates resolving EMI-related concerns.

While power integrity (PI) is often regarded as a separate matter from SI, it is important to recognize their intricate relationship. Overlooking proper thermal management methods can exacerbate your EMI problems. To achieve the best possible outcomes, it is imperative to adhere to EMI design guidelines that encompass all aspects of PCBA design affecting SI/PI.

PCB Design Considerations for EMI Minimization

Noise or electromagnetic interference (EMI) can be defined as unwanted electrical or magnetic energy in locations where it should not exist. In the context of electronic circuit boards, this refers to energy within the PCBA structure, on its surface, or nearby that can adversely affect the board’s signals. The latter scenario, often caused by nearby PCBAs or electronics, is typically categorized as an electromagnetic compatibility (EMC) issue. Mitigating PCB EMI and EMC concerns necessitates adherence to well-established design guidelines.

To achieve optimal EMI design, it is essential to consider the following factors and incorporate them into the design process.

Considerations For PCBA EMI Design Guidelines |

|

|

Design Consideration |

Why It’s Important |

|

Component Placement |

Components, especially high pin-count ICs, are a primary source of coupling and EMI on PCBs. Spacing between parts also defines trace separation at the source and termination points. |

|

Trace Routing |

Balanced mutual coupling between differential RF traces is good as it cancels interference. However, unbalanced differential routing and coupling of different signals will degrade SI/PI. |

|

PCB Stackup |

A good stackup design helps with grounding and impedance control while minimizing PI degradation due to transients. |

|

Impedance Control |

Matching impedance is critical for RF routing, power transfer, and good SI. |

|

Filtering |

Filtering is one of the most common methods of controlling EMI; however, choosing EMI components and placement locations is a design issue. |

|

Grounding |

The types and location of ground pads, planes, and traces, is foundational for circuit design. Bad designs can not increase EMI but also create issues like stray capacitance. |

|

Shielding |

Instead of routing unwanted signals to the ground, shielding is an effective means of blocking radiated EMI and isolating the EMI source from other board elements. |

|

Thermal Management |

Heat is energy and can generate/increase unwanted current flow. Therefore, preventing hot spots and removing excess heat efficiently help minimize EMI. |

EMI minimization is a multifaceted challenge, as evident in the table above, with numerous potential sources. It is important to acknowledge that completely eliminating unwanted signals and radiation from your board is highly unlikely, given that the fundamental operations of electronic circuits generate electrical and magnetic fields. However, the adverse effects on signal integrity (SI) and power integrity (PI) caused by EMI can be significantly mitigated by following effective EMI design guidelines.

EMI Design Guidelines for SI/PI Optimization

To optimize SI/PI and ensure the successful attainment of your PCBA’s operational goals, it is crucial to address and control various forms of EMI, including noise, ringing, ripple, inductive and capacitive coupling, and other sources. Although challenging, adhering to the following best practices for EMI minimization will help alleviate any substantial negative impact on your board’s functionality and structural integrity.

Best Practices for Minimizing EMI on Your Circuit Board |

|

Component Placement |

|

Trace Routing |

|

Stackup |

|

Impedance Control |

|

Filtering |

|

Grounding |

|

Shielding |

|

Thermal Management |

|

Following the guidelines listed above will go a long way in ensuring that your PCBA does not suffer from excessive EMI.

If you’re looking for CAD models for common components or design information on the most effective EMI design guidelines, Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.