Thermal analysis of electronic components like amplifiers is important to ensure operationality and reliability

Prior to the introduction of transistors, vacuum tubes were the common electronic devices used for amplification. These parts were functionally adequate for the systems in which they were used. In addition to being bulky, the tubes were exposed and could be notoriously unsafe.

Although, the days of seeing smoke coming out of your TV or appliance have largely disappeared, the potential for heat events still remains. In most cases, these contingencies are due to circuit board elements that become overheated. Results can range from product failure to physical harm for users. Therefore, it is important to know why and how to incorporate thermal analysis of electronic components into your PCB design.

What Components Need Thermal Analysis?

Fundamentally, any energy exchange; such as current flow through a conductor, generates heat. Therefore, the thermal characteristics of all components used in electronics systems are important. There are applications; such as high power density devices, where the criticality of thermal management demands consideration during PCB design. However, excessive heat can be a problem on any board due to unforeseen operation issues like external power supply current surges, or preventable issues like inadequate thermal dissipation design.

Thermal analysis is typically necessary for the types of devices listed below.

|

WHEN THERMAL ANALYSIS OF ELECTRONIC COMPONENTS IS NEEDED |

|

|

Device Types |

Electronic Components |

|

Power Supplies |

DC-DC converters, inverters, batteries and battery packs and support devices |

|

High power devices |

MIcroprocessors, microcontrollers, FPGAs, transformers, relays |

|

Antennas and other components that emit significant electromagnetic radiation |

|

|

Resistors, capacitors, inductors |

|

|

Power cables, data cables |

|

As shown above, many of the components you use; including common active and passive parts, may require thermal analysis. Criterion may vary according to the specific device type and application, but ensuring operational and safety concerns are generally the motivation for thermal analysis of electronic components.

Why is Component Thermal Analysis Important?

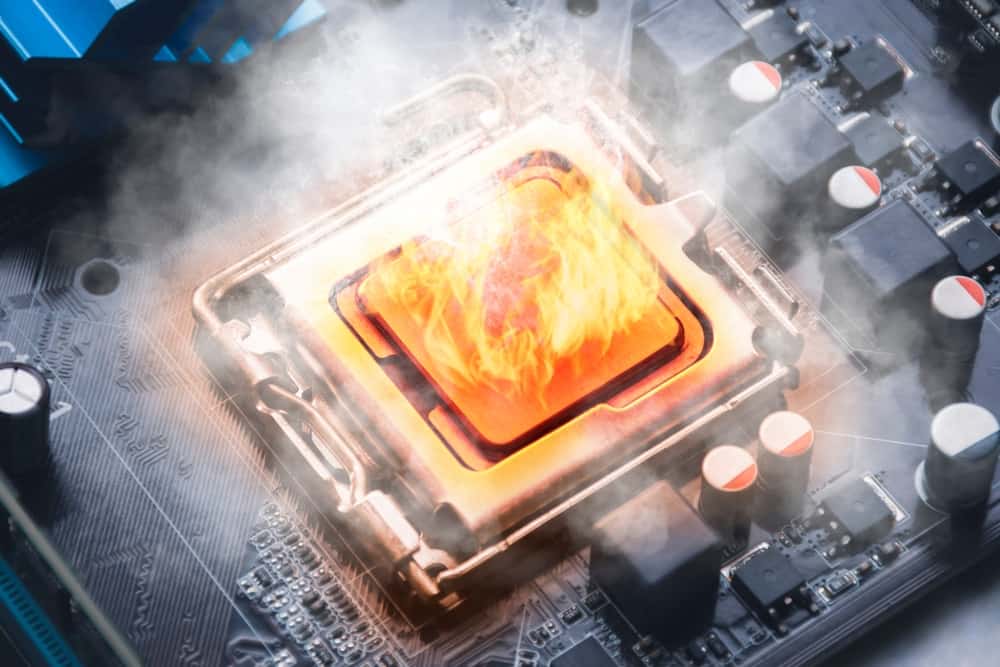

Good thermal analysis of electronic components will help avoid part damage

Although occurrences are far less common, today’s circuit board components can burst into flames, just as vacuum tubes did. This is but one, albeit a severe one, of the issues that excessive heat can cause on PCBAs.

Results of Overheated Components on Circuit Boards

- Erractic or loss of functionality

- Open circuits

- Part damage

- Trace damage

- Board structural damage

- System level operation interruption

- Harm to nearby persons

When components are exposed to temperatures beyond the limits of their thermal capacity, the effects can be disastrous. And depending on your board’s application, these effects may threaten the safety of users. Consequently, thermal management is a primary design imperative for critical applications like automotives, aerospace, and military systems.

Incorporating Component Thermal Analysis into Your Design

Many industry standards include PCB testing and performance requirements meant to guard against failures; such as for automotive systems, that can result in personal injury or worse for users. These regimens typically include specifications for reliability due to thermal, as well as electrical and mechanical contingencies. However, for boards that may fall into IPC class 1 or 2, oversight may be as stringent. Nevertheless, to ensure that your board will reliably satisfy its functional and operational objectives, you should know and follow good thermal analysis of electronic component guidelines for your design.

|

Guidelines for Thermal Analysis of Electronic Components PCB Design

|

As indicated above, good thermal analysis of electronic components necessitates that you take the thermal operation of your parts and board into consideration at all stages of design; including selections for the components and board material. By only using CAD data and information, like datasheets, from a reliable source help to ensure that the models and specifications used for performing thermal analysis simulations are accurate and can be relied upon for your board build.

If you’re looking for CAD models for common components or important information for instituting thermal analysis of electronic components into your PCB design process, Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.