Nearly all printed circuit board projects require CAD data from component manufacturers to ensure accurate integration during assembly. Accessing this information is trivial for most component manufacturers (although designers or design teams may still have to generate their land patterns manually or use wizard tools). However, this information may be difficult to find if the manufacturer’s documentation practices are sub-standard. For CAD file downloads, it’s important to know the minimum necessary information to ensure designs are manufacturable.

CAD File Download Contents

CAD file downloads should include four essential elements:

- The SPICE symbol for logic simulations and circuit analysis.

- The schematic symbol with the pinout (pin names/numbers) provided by the manufacturer.

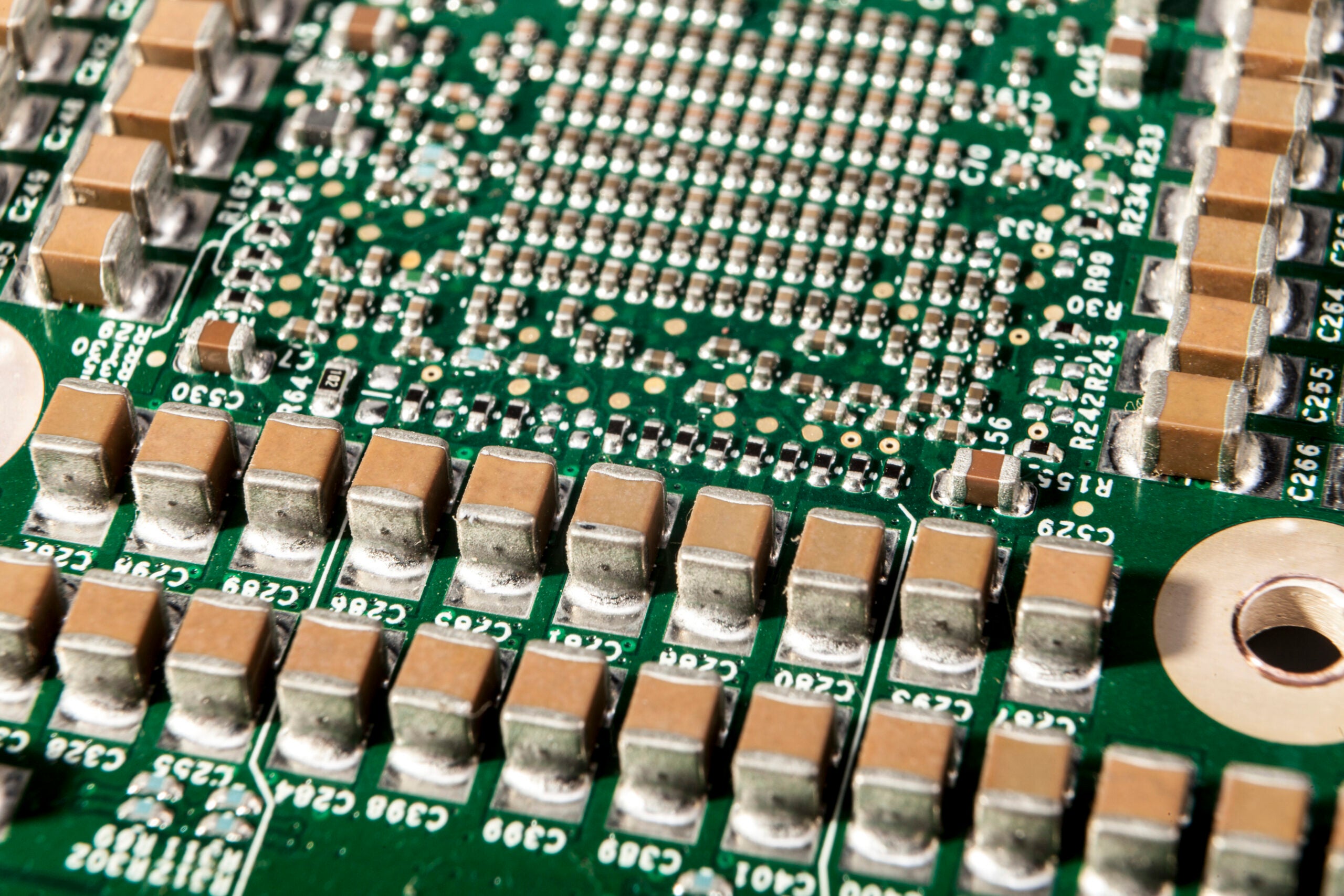

- The component footprint for proper spacing and solderability of the component.

- A 3D model for visualization of the board and potential assembly issues (e.g., shadowing, rework, etc.)

Each of these four elements represents a critical stage of the board development.

|

PCB CAD FILE ELEMENTS UTILIZATION |

|

|

CAD File Download Element |

Corresponding Board Design Stage |

|

SPICE Symbol |

Before designers consider a physical board, a logical proof-of-concept is necessary. SPICE, a broad family of circuit simulation languages, allows design teams to rapidly develop and alter circuitry without investing in component costs or board layouts. |

|

Schematic Symbol |

Once simulations are complete, engineers build the schematic to encapsulate all the board’s connectivity. The schematic symbol is one-half of the information necessary for board layout: it associates pin names and numbers with the nets between components to form the design netlist. |

|

Component Footprint |

Within the schematic, and before outputting the netlist, designers need to associate footprints with the schematic symbols to establish a logical relationship between components, the physical dimensions of the package, and related manufacturing processes. |

|

3D Model |

Modern design software supports 3D modeling of components to visualize the assembled PCB. 3D modeling can identify potential issues of component placement density (like limited access to low-profile SMD components neighboring higher-profile connectors that inhibit manual and automated soldering) and is extremely useful for complicated system assemblies for flex and rigid-flex designs. |

The fastest and simplest solution is for designers to retrieve this CAD information directly from the manufacturer. However, some data may be outdated, missing, paywalled, or behind contact forms, making retrieving this information challenging for some PCB designers.

Dedicated Librarians Just Clicks Away

Of course, not all CAD files are readily available. Mergers, acquisitions, component obsolescence, and poor documentation can make tracking OEM information difficult. In these cases, designers or design teams must invest effort into creating their own CAD data; board manufacturers may encounter component insertion, placement, or soldering issues without careful design considerations. Ideally, an internal verification process catches any issues with CAD symbol creation. However, slight differences in dimensions, pinouts, or orientations can become considerably costly to correct through rework or a board revision.

Ultra Librarian users can bypass these snafus with the Virtual Librarian Service (VLS). Beyond the millions of prebuilt and verified components available to Ultra Librarian users, VLS offers a dedicated, custom librarian who can source even complex CAD data and create new footprints as necessary. Designers or teams can focus their precious time on core project aspects rather than the ancillary details. And with custom footprints available in as little as twenty-four hours, project timelines won’t suffer. VLS also includes symbols that adhere to organizational specifications, 3D models, and verification of all generated CAD data.

A Complete CAD File Solution

Ensuring CAD file downloads contain the necessary information for manufacturers with verified footprints is a critical step to avoid costly rework or layout revisions before entering production. The historical method of having a dedicated librarian or layout designer may not suit all organizations; Building and maintaining an effective component library that is supply chain resilient requires expertise and substantial time commitment.

Working with Ultra Librarian, the industry leader for CAD file downloads is the most efficient solution. We can build you a customized Virtual Librarian Service that will streamline component selection, ensure parts meet your standards, expedite procurement, and optimize your PCBA development process for innovation. To learn more, schedule a meeting and learn how partnering with UL sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.