Electronic component pricing forecast graph

Electronic component pricing forecast graph

Roughly 2500 years ago, Greek philosopher Heraclitus is purported to have asserted “…the only constant in life is change.” Nothing could more aptly describe the recent volatility of electronic component prices. Understanding this uncertainty requires delving into the many factors that drive component price trends.

Unfortunately, some impactful cost factors are unpredictable; such as the availability of raw materials, governmental policies that affect trade, and global events, like the COVID-19 epidemic. Conversely, other trends tend to follow discernible patterns. Among these are production capacity, customer demand, and labor capacity.

As ROI for design and development and profitability depend on how well costs, especially for components, are managed, it is important to adopt a strategy to mitigate the negative impact that price fluctuations can cause. The best foundation for this cost management plan is supply chain resilience, which begins with knowing price trends and understanding electronic component pricing factors.

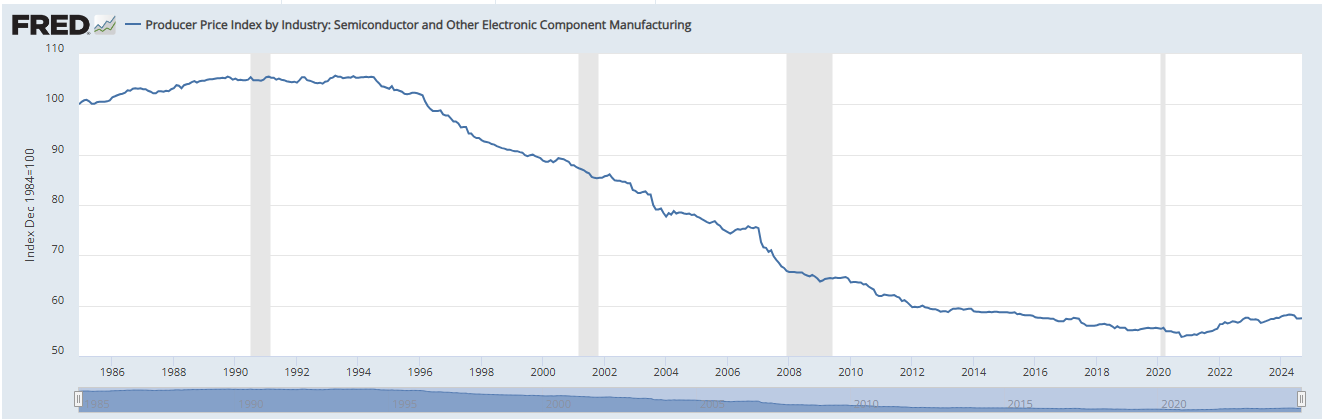

Pricing Trends for Building Circuit Boards

As shown below, the producer price index (PPI)–which measures average price change over time for component manufacturers/producers–steadily declined from the early 1990s to early 2020s.

Fig. 1 Current KPIs for PCBA CMs

The period of declining prices occurred not in spite of, but because of tremendous growth in electronic component sales and electronics utilization due in large part to consumer demand for smaller, more functional circuit boards and electronics products. There are several key factors that typically drive trends; such as this.

Factors That Drive Electronic Component Pricing

When sourcing components for your design, a simple head-to-head price comparison to decide which way to go for your project might be ideal. This can be effective for single components with identical IC manufacturing codes—which indicates the parts were built by the same company but from different distributors.

However, when these prices vary greatly, or you are researching different components with similar performance characteristics, there may be other considerations you should be aware of, as listed below, that may influence electronic component pricing differences.

Cost Drivers for Electronic Component Pricing

- Manufacturer reputation

Parts built by manufacturers that have a reputation for producing high-quality, reliable parts may be higher priced; however, you can be assured they are true to datasheet specifications.

- Component utilization

Similar to manufacturer reputation, but with a different impact, components that have been around for a long time and used by developers for many applications tend to have lower prices than when they were introduced due to high sales volume.

- Part materials

Electronic component pricing is also significantly influenced by the quality of materials used to manufacture them. Often you can find similar parts cheaper, due to the use of cheaper materials.

- Obsolescence

All components have a product lifecycle, at the end of which a newer, more advanced part typically takes its place. This period can be a few years to decades, depending upon technological development and application demands. Distributors will often lower prices to clear substantial inventories of these types of components.

- Availability

In recent years, while material costs were increasing, inventories were mostly declining. This is a reaction to the global component shortages that continues to impact PCBA development across many industries—the hardest hit are automotive and medical devices.

All but the last cost driver for electronic component pricing listed above are normal, albeit not constant. However, component shortages are unplanned contingencies that will continue to play a significant role in electronic component pricing for the foreseeable future, and therefore must be considered in supply chain resiliency plans.

Securing Your Component Supply Chain Against Fluctuating Prices

As shown in Fig. 1 above, current trends for electronic component pricing basically trend upward. Yet, prices for components can rise or fall for various reasons, as discussed in the previous section, and the best predictions may prove to be unreliable. The best way to interject consistency into your component expenditures is by incorporating actions and adopting a strategy for securing your component supply chain, which includes the following guidelines.

How to Mitigate Electronic Component Pricing Fluctuations

- Buy in bulk

As components are expected to continue to rise and guard against the unavailability of critical parts, it is a good idea to bulk buy. Yes, there may be some risk of overstocking; however, when compared against not being able to fill customer orders, it is likely worth it. Moreover, unless the components are highly specialized, they can be repurposed for other board designs if it becomes necessary.

- Do not employ a Just-in-Time (JIT) development strategy

JIT typically refers to a lean manufacturing process utilized to shorten process times within development and reduce costs. Component procurement should be streamlined as much as possible to what will actually fulfill the latter. Unfortunately, in the present climate, this can backfire and result in backlogs for components.

- Employ techniques to improve the efficiency of your board development process

Increasing component costs can also be mitigated by reducing costs and/or time in other areas of development. For example, if prototyping perform simulations—signal integrity and thermal, for example—during design to minimize the number of board spins required to achieve a production-ready design. Employing PCB testing by your CM may also be used to lower post-design validation testing by a third party.

- Build and use a custom component library

Component and design costs can be more easily managed by reusing proven components, sub-assembly and full board designs. A custom component library built on CAD models and data from reliable sources serves as a reservoir that helps guard against cost fluctuations associated with new components, minimize design and development time, and to avoid negative contingencies like counterfeit components.

The suggested actions above and other PCBA development optimization steps will help secure your supply chain and offset the unpredictability of electronic component pricing during the current global parts shortage and beyond.

If you’re looking for CAD models for common components, the best PCBA design advice or relevant information that you can use; such as how to mitigate the fluctuations of electronic component pricing, Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.