Do your designs need to connect to the outside world? Then you need electrical connectors. The options you’ll find for connectors are more diverse than anything you’ll see in the semiconductor space. Various form factors, pin configurations, housings, locking mechanisms, and electrical ratings are available from multiple vendors, some of which are standardized for high power and/or data rate applications. Some systems require highly ruggedized connectors that meet MIL-DTL standards, SAE standards, or even high data rate protocols like Ethernet and USB.

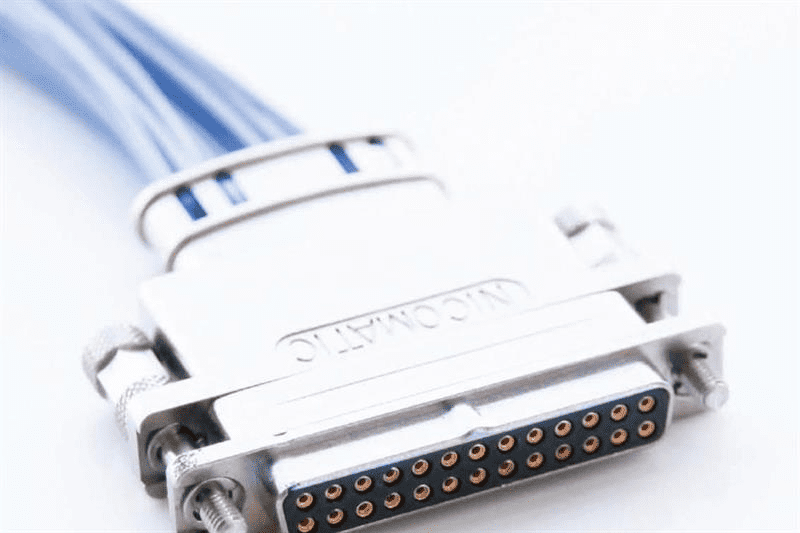

The CMM and DMM series of connectors from Nicomatic are designed for use in rugged environments like industrial systems, automotive or aerospace, and robotics. These two connector series are similar in terms of form factor and ruggedization, and they are both modular in terms of construction. While there is no datasheet for these connectors, you can find the information you need if you look at the product catalogs for these products.

Nicomatic CMM and DMM Connectors

Both the CMM and DMM connector series are intended respectively as substitutes for D-sub and Micro-D connector components in aeronautics systems. The main points CMM and DMM connectors have in common are their pin pitch of 2 mm and modularity. The 2 mm pin pitch is used in more rugged connectors requiring a larger molded connector body and cable assembly. Nicomatic’s connector options are intended to be modular so that users can customize their pin count (both row and contact number), pin contact type (power/signal/RF), and mounting style.

The various contact types, mounting options, backshell options, pin counts, and row counts make this series totally modular, and designers can customize their own connector options. These rugged connectors can be easily customized using the Nicomatic part selector on the company website to determine the part number corresponding to your modular connector option. Depending on the specific parts within these series, designers can mix pin contact types to provide signal, RF, and power in a single interconnect.

CMM Series Specifications

These D-sub alternatives provide multiple combinations of pin contacts and mounting styles to give a fully modular, board-mountable connector style. Board mounting options include through-hole and SMT at right angles or vertically, allowing connection to a cable through the enclosure. The same connector style could be used for a board-to-board connection to another right-angle or vertical connector of the same style. These arrangements of connectors allow rugged multi-board assemblies to be built with totally custom pinouts.

CMM connectors from Nicomatic are intended as rugged alternatives for these D-sub connectors.

DMM Series Specifications

The DMM series of connectors from Nicomatic is designed to be a rugged alternative to Micro-D or Sub-D connectors. In terms of application within a system, they provide a flange for wall/panel mounting and the standard board/wire interconnect options. One-piece or two-piece backshells are available for these connectors to provide full mechanical and electromagnetic shielding of the entire connector assembly, similar to other shielded connector options. These connectors are designed to comply with MIL-DTL-83513G performance standards.

Aside from the difference in primary MIL-DTL standards compliance, the DMM series has one-piece or two-piece backshell options that make it a more rugged option than the CMM series:

- Mechanical protection from backshells: This helps eliminate tension directly on the connector pins and instead transfers it to the housing. This helps prevent tension exerted on a cable assembly from damaging the contact solder or crimping connections in the connector assembly.

- EMI protection from backshells: The metal backshell of these connectors provides 360° shielding against EMI/RFI (following MIL-STD-1377) with transfer impedance Zt < 200 mOhm at frequencies ranging from 10 kHz to 400 MHz.

Contrary to popular belief, a metal backshell does not aid thermal management in connectors or prevent damage from heat. Instead, the insulator material is more important and will prevent heat from damaging the crimped connections or from traveling into the mating connector. Therefore, consider the insulator type (see below) if thermal protection is an important criterion for selecting rugged connectors.

Summary of Specifications

The table below summarizes some of the key specifications for the Nicomatic CMM and DMM series of modular rugged connectors. These specifications are often the starting point for selecting rugged Micro-D connector options.

| CMM | DMM | |

| Number of combinations | Approximately 20M | Approximately 10M |

| Standards compliance | MIL-DTL-55302F | MIL-DTL-83513G |

| Mounting style | – Board to board

– Board to wire – Wire to wire |

– Board to board

– Board to wire – Wire to wire – Panel mount (1 to 4 rows of contacts) |

| Pin pitch | 2 mm | 2 mm |

| Backshell | Single-piece accessory (6061 aluminum) | Integrated one-piece or two-piece options (6061 aluminum) |

| Insulator | PPS 30% GF | PPS 30% GF |

| Mating cycles | Rated up to 500 | Rated up to 2500 |

| EMI conformance | N/A | MIL-STD-1377 |

| Ingress protection | IP67 | IP67, or IP68 with O-ring |

From the above list of technical specifications, it should be clear that the DMM connector series will be the more rugged option. However, for applications that require fewer mating styles and no panel mounting, the CMM option is acceptable and is more configurable than the DMM.

When you need to find a list of all possible part numbers and sourcing information for Nicomatic CMM and DMM connectors, use the complete set of parts search features in Ultra Librarian. The Ultra Librarian platform gives you access to PCB footprints, technical data, and ECAD/MCAD models alongside sourcing information to help you stay ahead of supply chain volatility. All ECAD data you’ll find on Ultra Librarian is compatible with popular ECAD applications and is verified by component manufacturers to help streamline your designing process.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.