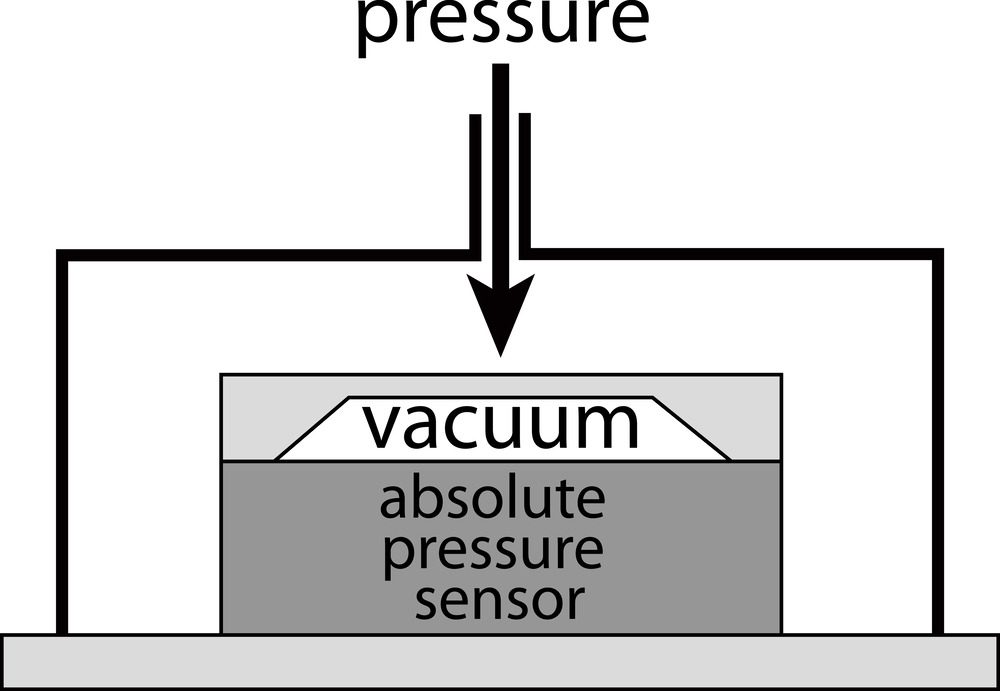

Why do designers need an absolute pressure sensor? We all know that earth’s atmosphere exerts its pressure, also known as ambient pressure. It varies with weather conditions. When measuring blood pressure or tire pressure, sensors use ambient pressure as a reference. But specific applications require readings not to be influenced by weather or atmosphere.

That’s where the role of an absolute pressure sensor like the SCP1000 goes imperative. In this regard, understanding the SCP1000 datasheet further enables designers to acknowledge its importance for other applications in pressure chambers, planes, submarines, and more.

Absolute Pressure Sensor – A Brief Overview

An absolute pressure sensor measures the pressure of the target environment against an absolute vacuum. These sensors are specially used in altimeters and barometers for reading vacuum-referenced pressure. They are uninfluenced by altitude and weather conditions and highly sought-after by metrological and aviation applications.

The operating principle of the sensor follows Boyle’s Law states that at a constant temperature, the pressure of a gas is inversely proportional to its volume. Using this principle, one sensor side is exposed to an absolute vacuum (0.0005 PSI), whereas the other side registers the external pressure. The change in strain is measured using a Wheatstone bridge embedded inside the chip. Then, the sensor transfers the data to a microcontroller for further analysis. However, the sensor may require periodic compensation and calibration against external factors, such as temperature.

Understanding the SCP1000 Datasheet

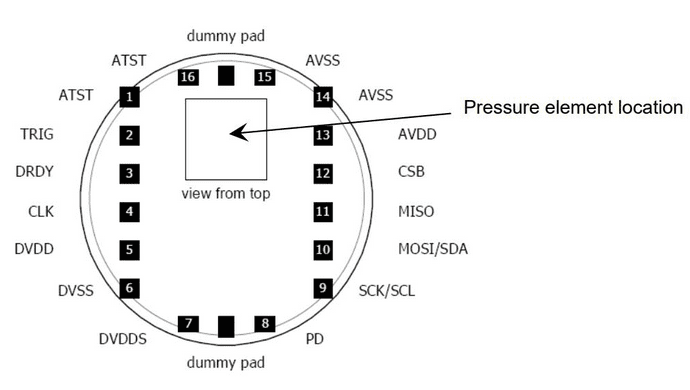

Pin Layout

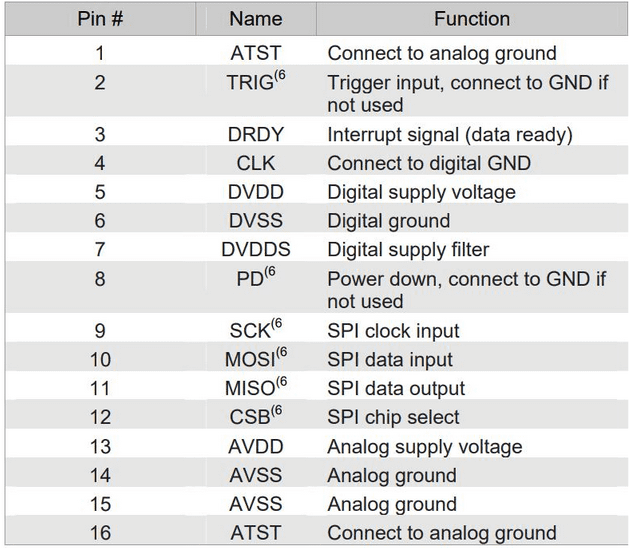

The sensor can support both SPI and I2C interfaces. While the former setting requires MOSI, MISO, SCK, and CSB pins to connect the sensor with the microcontroller, the I2C interface requires SDA (pin 9) and SCL (pin 10) to go high.

The datasheet also suggests shouldering the pin pairs (1,16) and (14,15) for contact reliability. First, let’s understand the critical design parameters mentioned in the SCP1000 datasheet.

Absolute Maximum Ratings

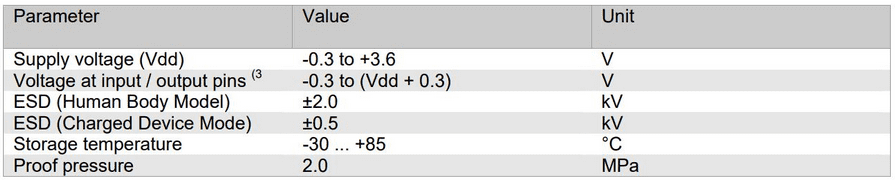

The sensor is safe to operate between -0.3 to +3.6 V. It also has internal ESD (electrostatic discharge) protection circuits. Therefore, the device can protect itself from accidental static discharges from any human body (2 kV) or charged device (0.5 kV). The proof pressure mentioned represents the maximum pressure applied to the device without hampering its performance within the specifications.

Electrical Characteristics

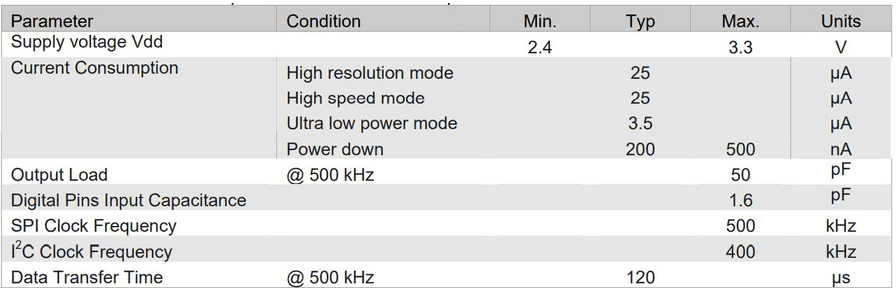

The sensor is safe to operate within a supply voltage range between 2.4V to 3.3V. The device consumes different amounts of current depending on the mode type selected, as shown in the datasheet.

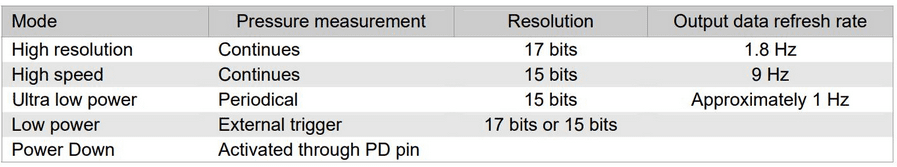

It consumes the lowest (200 nA) when idle and the highest (25 µA) when set to resolution mode or speed mode for continuous pressure measurement. For periodical pressure measurement, you can set it to Ultra Low Power mode, and the device consumes not more than 3.5 µA. The datasheet has also mentioned the resolution and the data refresh rate for each mode.

The SCP1000 supports I2C (Inter-Integrated Circuit) and SPI ( Serial Peripheral Interface) communication protocols. The product is available in two designs- SCP1000-D01 with SPI interface and SCP1000-D11 with I2C interface.

The SCP1000 supports I2C (Inter-Integrated Circuit) and SPI ( Serial Peripheral Interface) communication protocols. The product is available in two designs- SCP1000-D01 with SPI interface and SCP1000-D11 with I2C interface.

With the SPI interface, the sensor can send data fast in max of 120 µs at a clock frequency of 500 kHz.

The table below summarizes the difference between the two interfaces:

| SPI | I2C | |

| Communication | Full duplex | Half duplex |

| Interface | 4-wire type | 2-wire type |

| support | Single master | Multi master, multi slave |

| Clock stretching | Not available | Available |

| Speed | Fast | Slow |

For design considerations, you can further refer to the datasheet to understand the role and characteristics of different pins under SPI and I2C communication protocols.

Performance Characteristics

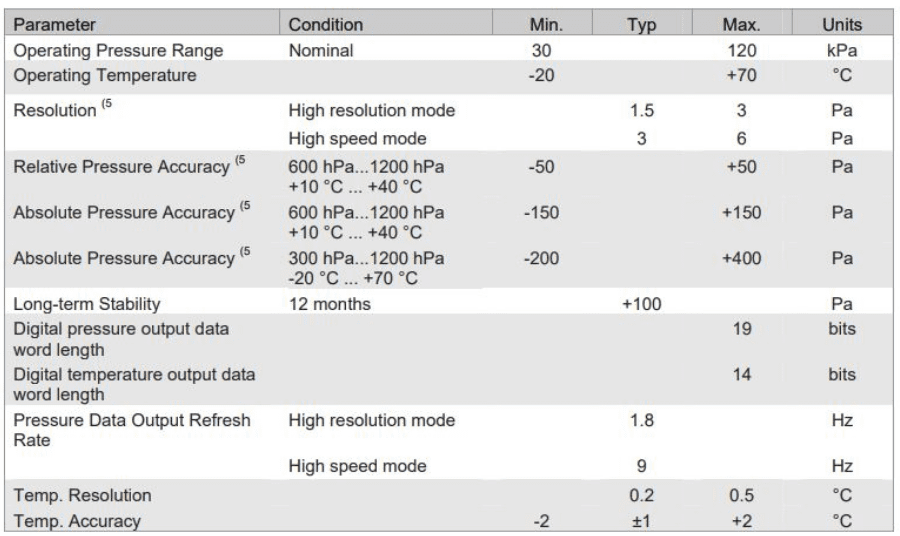

The SCP1000 sensor boasts a 30 kPa – 120 kPa measuring range with a typical resolution of 1.5 Pa. The relative accuracy information shows that when the operating pressure range is between 600 hPa-1200 hPa and the operating temperature range is 10 °C – 40 °C, the reading may deviate from the actual value by 50Pa max. Regarding absolute pressure accuracy (pressure against absolute vacuum), the reading may differ by 150 Pa max under the same condition.

However, we should consider harsh environmental conditions, as shown in the SCP1000 datasheet, the measured value may deviate from the actual value within a range of -200 Pa to +400 Pa. The sensor has an on-chip device measurement feature to read the temperature at a resolution of 0.2 °C at an accuracy of ±1 °C. Here, accuracy represents how close the reading can be to the actual value, whereas resolution states the minor change that can be measured.

Designing PCBA with the SCP1000

The SCP1000 datasheet contains pad layout and dimensions for design implementation. You may also make the best use of verified CAD models and 3D simulations of the device available in the online library of Ultra Librarian to create your own footprints. The library hosts CAD models, component data and sourcing information of all such common components in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.