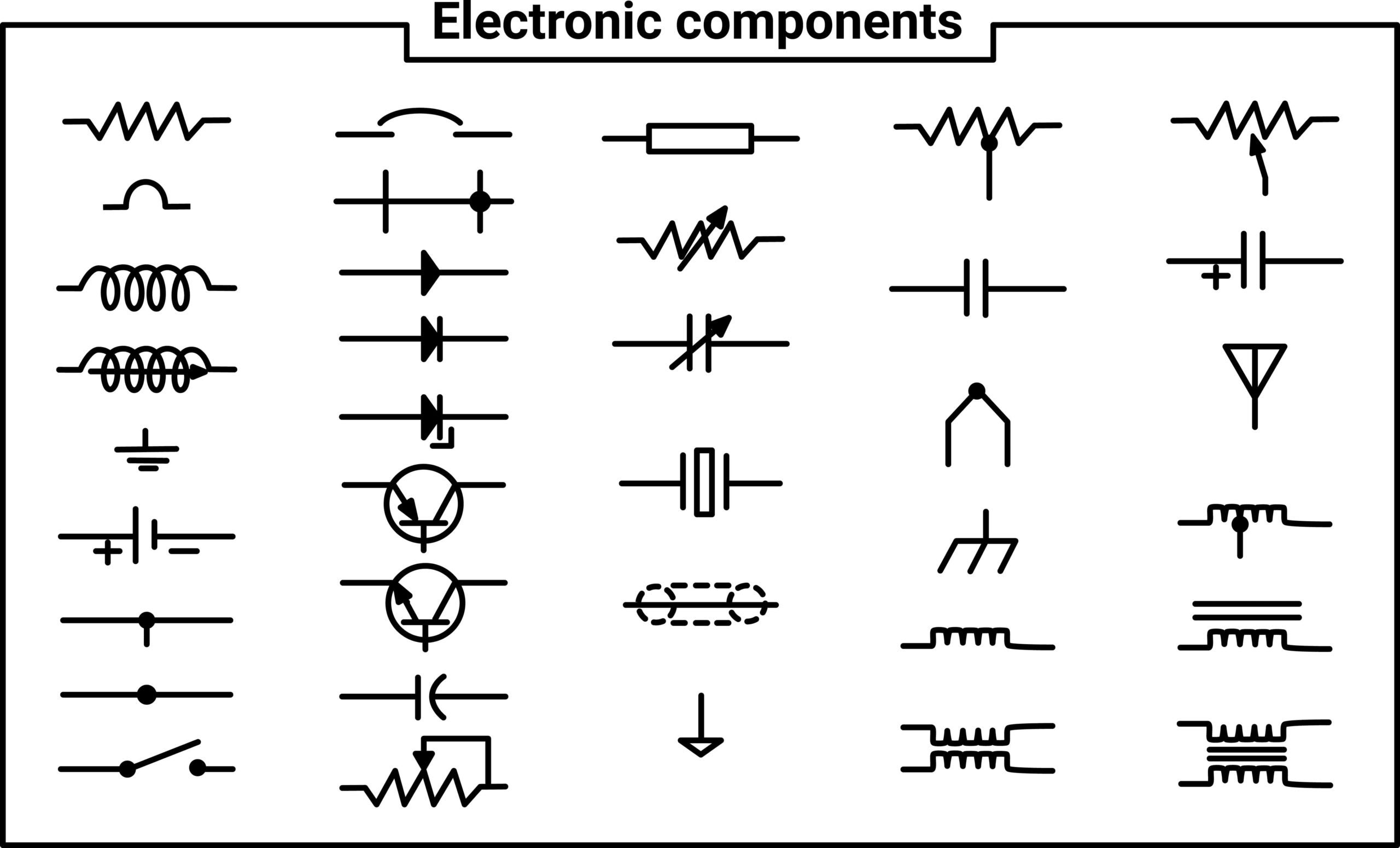

Accurate schematic symbols are essential for a reliable electronic components sourcing database.

An electronic components sourcing database is vital for PCB designers, as it is a comprehensive repository of accurate and up-to-date data on electronic components. The database streamlines the component selection process, ensuring designers can identify suitable design components, while avoiding supply chain disruptions like sourcing delays due to incorrect parts and counterfeits. By providing data on component specifications, availability, and compliance, the sourcing database allows designers to make informed decisions, optimize PCB layouts for efficient manufacturing, and maintain product quality and reliability throughout the development cycle.

Electronic Components Sourcing Database Attributes

The table below describes the most important attributes of an electronic components sourcing database.

|

ESSENTIAL ATTRIBUTES OF AN ELECTRONIC COMPONENTS SOURCING DATABASE |

|

|

Attribute |

Description |

|

Accurate Schematic Symbols |

Graphical representations for circuit design to ensure correct schematics integration |

|

PCB Layout Footprints |

Precise component layouts for proper placement and routing |

|

3D Models |

3D representations facilitating mechanical design and assembly visualization |

|

Up-to-Date Data |

Timely updates on component availability, pricing, and lifecycle status |

|

Counterfeit Detection |

Measures to detect and prevent the distribution of counterfeit components |

|

Alternative Sourcing |

Information on substitute components to mitigate sourcing disruptions |

|

Compliance Documentation |

Documentation ensuring compliance with regulatory and environmental standards |

|

Quality Control |

Processes to ensure components meet quality standards |

|

Traceability |

Systems guaranteeing the authenticity and origin of components |

|

Integration Support |

Compatibility with design tools and systems for product development integration |

Incorporating the attributes listed above in your electronic component sourcing database will significantly improve the speed and reliability of your PCB design and development by streamlining the procurement process, minimizing component quality risks, and aiding in board compliance verification and manufacturing efficiency.

Accurate Schematic Symbols

Schematic symbols are graphical representations of electronic components used in circuit diagrams. Accuracy in these symbols ensures that engineers can design circuits correctly without ambiguity.

Significance: Accurate symbols aid in clear communication between design engineers and facilitate error-free schematic designs.

PCB Layout Footprints

PCB layout footprints provide precise information about the physical dimensions, pad placements, and other layout details of components on a PCB.

Significance: Accurate footprints ensure proper component placement during PCB layout design, enabling efficient routing and minimizing the risk of errors or signal integrity issues.

3D Models

Three-dimensional CAD models represent components realistically, allowing for visualization and integration into CAD software for mechanical design and visualization of PCBs.

Significance: 3D models aid ECAD/MCAD designers in ensuring proper fit and clearance within the product enclosure, reducing the likelihood of mechanical interference or assembly issues.

Up-to-Date Data

Updates on component availability, pricing, lead times, and lifecycle status help avoid sourcing delays and ensure that designers can access the latest information when selecting components.

Significance: Keeping data current minimizes the risk of using obsolete or unavailable components, reducing redesign efforts and time-to-market delays.

Counterfeit Detection

Counterfeit detection measures include rigorous inspection, testing, and authentication processes to identify and prevent the distribution of counterfeit components.

Significance: Detecting counterfeit components helps maintain product quality, reliability, and safety while safeguarding against potential legal and financial risks.

Alternative Sourcing

Information on equivalent components serves as a backup plan in case primary components are unavailable or unsuitable, helping mitigate sourcing disruptions.

Significance: Having alternative sourcing options reduces dependency on single suppliers and minimizes the impact of supply chain disruptions, ensuring production continuity.

Compliance Documentation

Comprehensive documentation ensures that components comply with regulatory standards, industry specifications, and environmental laws.

Significance: Compliance documentation verifies the suitability of components for use in specific applications and markets, avoiding possible legal liabilities and market access issues.

Quality Control

Quality control processes include testing, inspection, and certification to ensure that components meet specified quality standards and performance criteria.

Significance: Maintaining high-quality components reduces the risk of product failures, warranty claims, and customer dissatisfaction, enhancing overall product reliability and brand reputation.

Traceability

Traceability systems track the origin, authenticity, and movement of components throughout the supply chain, helping prevent the use of counterfeit or substandard parts.

Significance: Traceability enhances supply chain transparency, enables timely recalls or corrective actions, and strengthens quality assurance efforts, safeguarding product integrity and customer trust.

Integration Support

Compatibility with design tools, CAD software, and enterprise systems ensures seamless integration of component data into the product development process.

Significance: Integration support streamlines workflow efficiency, facilitates collaboration between cross-functional teams, and enables faster decision-making during design and manufacturing phases.

A robust sourcing database ultimately enhances design efficiency, minimizes risks, and accelerates time-to-market for electronic products.

If you’re looking for CAD models for common components or important information on creating an effective electronic components sourcing database, Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Building and maintaining an effective component library that is supply chain resilient requires expertise and substantial time commitment. Working with Ultra Librarian is the most efficient solution. We can build you a customized Virtual Librarian Service that will streamline component selection, ensure parts meet your standards, expedite procurement, and optimize your PCBA development process for innovation. To learn more, schedule a meeting.