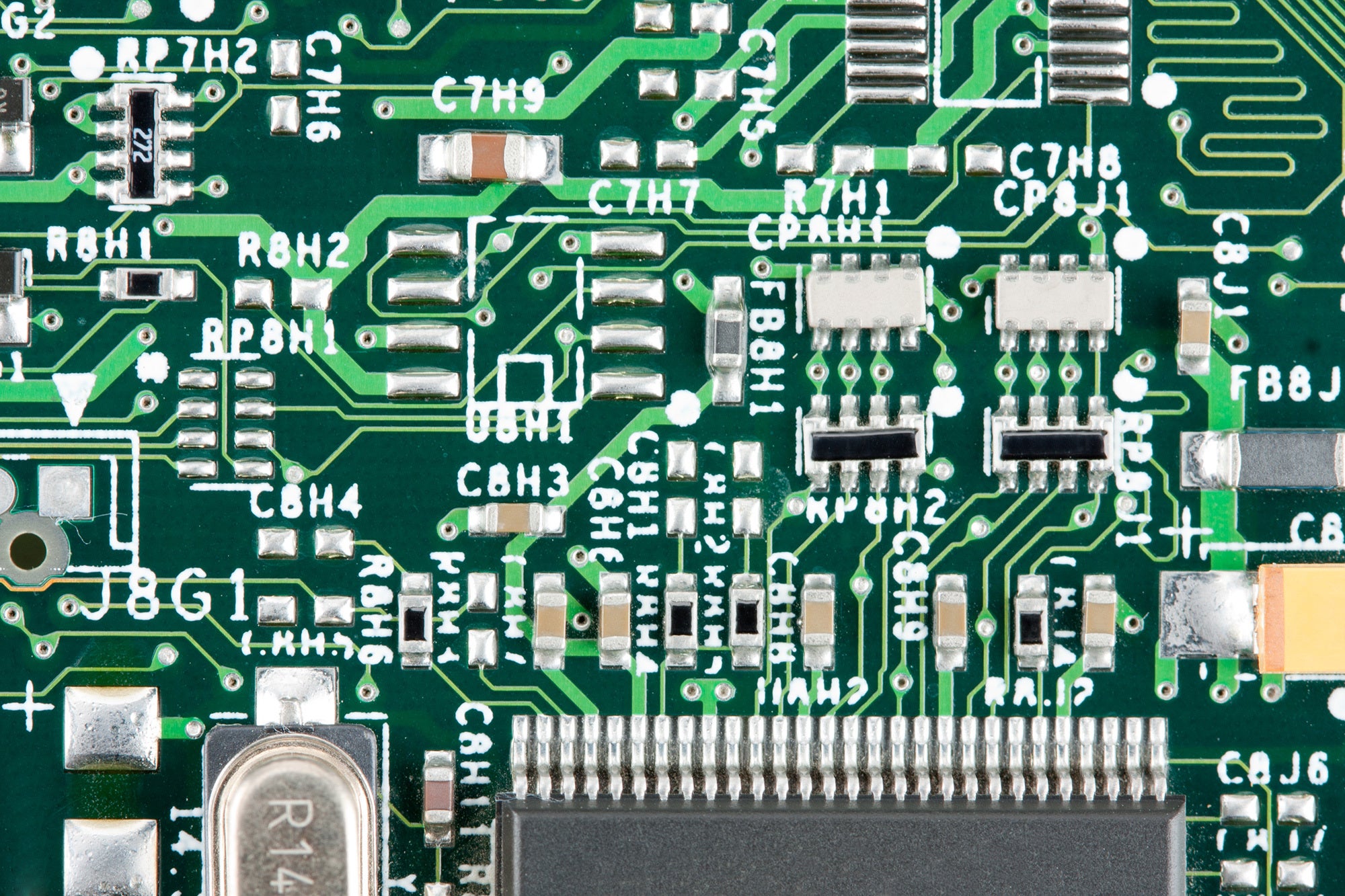

Electronic component reliability databases enable reliable PCB design and manufacture

Electronic component reliability databases are structured data collections for assessing and predicting electronic component reliability, failure rates, and lifecycle performance. Using historical data, environmental stress factors, materials properties, and operational conditions, they assist engineers and manufacturers in selecting components, assessing risks, and maintaining their products. These databases support reliability modeling, failure mode analysis, and supply chain management, ensuring that electronic systems meet industry performance and durability standards. Here are use cases and tools for electronic component reliability databases.

Electronic Component Reliability Database: Uses and Tools | ||

Use Case | Description | Tools |

Failure Rate Prediction | Estimates component failure probability over time. | MIL-HDBK-217, FIDES, Telcordia SR-332 |

Reliability Modeling | Creates mathematical models to predict reliability. | SiliconExpert, ReliaSoft Weibull++, RAM Commander |

Lifecycle Analysis | Assesses the expected lifespan of components. | Life Cycle Cost Analysis (LCCA), RELEX |

Failure Mode and Effects Analysis (FMEA/FMECA) | Identifies and evaluates potential failure modes. | Xfmea, Siemens Simcenter, Windchill Quality |

Component Selection | Helps engineers choose reliable components. | Ultra Librarian, SiliconExpert, IHS Markit, Zuken |

Obsolescence Management | Tracks component availability and alternatives. | Z2Data, IHS Parts, SiliconExpert |

Environmental Stress Analysis | Evaluates component behavior under extreme conditions. | HALT, HASS, Siemens Simcenter |

Accelerated Life Testing | Supports stress testing to predict component lifespan. | ALT, ReliaSoft ALTA, Weibull++ |

Predictive Maintenance | Uses AI and data analytics to forecast failures. | IBM Maximo, MATLAB Predictive Maintenance |

Supply Chain Risk Management | Assesses risks related to component sourcing and quality. | SiliconExpert, IHS Markit, Z2Data |

Electronic Component Reliability Database: Benefits for Engineers

Electronic component reliability databases offer significant advantages for engineers, particularly in designing, testing, and maintaining electronic systems. Here’s how they benefit engineers:

1. Informed Component Selection

Engineers can choose components with verified reliability data, ensuring better performance and reducing failure rates.

2. Enhanced Design Reliability

Engineers can design more robust and fault-tolerant systems by using reliability metrics like mean time between failures (MTBF) and failure rate.

3. Failure Mode Analysis

Engineers can use these databases to figure out common failure modes so that they can mitigate problems.

4. Accelerated Product Development

Pre-analyzed reliability data reduces the need for in-house testing, speeding up design and validation.

5. Cost and Time Savings

Choosing reliable components reduces rework, warranty claims, and system downtime.

6. Regulatory and Industry Compliance

Using verified component data, aerospace, automotive, and healthcare engineers can ensure their designs meet stringent reliability standards.

7. Predictive Maintenance Planning

Reliability data helps engineers design systems with predictive maintenance capabilities, reducing unexpected failures.

8. Supply Chain and Procurement Support

Engineers can work with procurement teams to find high-reliability components so counterfeit or low-quality parts don’t affect performance.

Ultra Librarian’s Librarian Tool

Ultra Librarian provides engineers with verified CAD models, footprints, and symbols for millions of electronic components. Using the librarian tool, engineers can quickly integrate accurate component data into their designs. The librarian tool has these features:

Standardized Component Libraries

- Ensures that footprints, 3D models, and symbols conform to industry standards (IPC, IEEE, JEDEC, etc.).

- Reduces errors in PCB design by providing pre-verified component data.

Multi-CAD Compatibility

- Supports integration with various EDA (Electronic Design Automation) tools like Altium, KiCad, Eagle, OrCAD, and others.

- Allows seamless transfer of component models across different design platforms.

Component Data Verification

- Ensures components meet manufacturers’ specifications, reducing the risk of errors and mismatches.

- Helps engineers avoid incorrect or outdated footprints that can lead to design failures.

Customization and Library Management

- Engineers can customize footprints and symbols based on specific design requirements.

- Companies can maintain internal libraries while ensuring consistency across design teams.

If you’re looking for CAD models for common components or important information on how to integrate electronic component reliability database capabilities into your design process , Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.