PCB and IC supply chain management is crucial to ensure the continuous quality of manufactured electronics. Electronic supply chains are vulnerable to counterfeit parts and logistics problems, which interrupt the flow of reliable components. These problems have been persistent since the beginning of distributed electronics manufacturing, but new methodologies for PCB and IC supply chain management have the potential to dramatically improve the reliability of electronics and their components.

PCB and IC supply chain management is crucial to ensure the continuous quality of manufactured electronics. Electronic supply chains are vulnerable to counterfeit parts and logistics problems, which interrupt the flow of reliable components. These problems have been persistent since the beginning of distributed electronics manufacturing, but new methodologies for PCB and IC supply chain management have the potential to dramatically improve the reliability of electronics and their components.

What Does Current PCB and IC Supply Chain Management Look Like?

Supply chain management is a complicated undertaking with many important elements. Hardware, software, logistics, and social relationships are integral to the PCB and IC supply chain. Each of these pieces can be an opportunity for vulnerabilities; threatening the quantity or quality of a product. As the manufacturing industry becomes more interconnected—distributing across the globe—communication at all levels of the supply chain has become more and more important. The supply chain is not a linear progression of steps, as its name might suggest, but a network of people, companies, and products interacting with each other.

Counterfeit parts are a major issue in the PCB and IC supply chain, and the recent impact on the electronics industry by COVID-19 has exacerbated the problem. Supply distribution has caused resource problems for many electronics suppliers, leaving room for less reputable suppliers to step in with less reliable parts. This has also caused changes in transportation and warehouse efficiency, causing delays in transit of parts to suppliers. Electronic manufacturers are also being impacted by difficulties with their corporate partners, whether they are suppliers, providers of raw materials, or marketing professionals.

The COVID-19 pandemic has proven current models of PCB and IC supply chain management aren’t as robust as they could be. Difficulties across the supply chain have emphasized the places where substandard parts, logistics difficulties, or other issues could derail production. Fortunately, new ideas for supply chain management may be able to solve some of these issues and make sure reliable components are available.

Which New Ideas for PCB and IC Supply Chain Management Show Promise?

One recent idea to improve management and security for PCB and IC supply chains is to use blockchain strategies in securing and tracking electronics hardware. Software for electronic devices gets a lot of attention in terms of security, but hardware security also deserves some focus. Cybersecurity experts have proposed a framework based on certificate authentication, ensuring the integrity and quality of hardware.

This framework handles critical information contained within electronic chips, which can verify the integrity and quality of the hardware. The framework is decentralized and generic, so it’s not easy to hack or disable, and many types of electronics can use it. This proposed idea would create a compatibility layer of sorts, simplifying access to the complicated globalized supply chain. This would make authentic and reliable components easier to track at every stage of their life cycle.

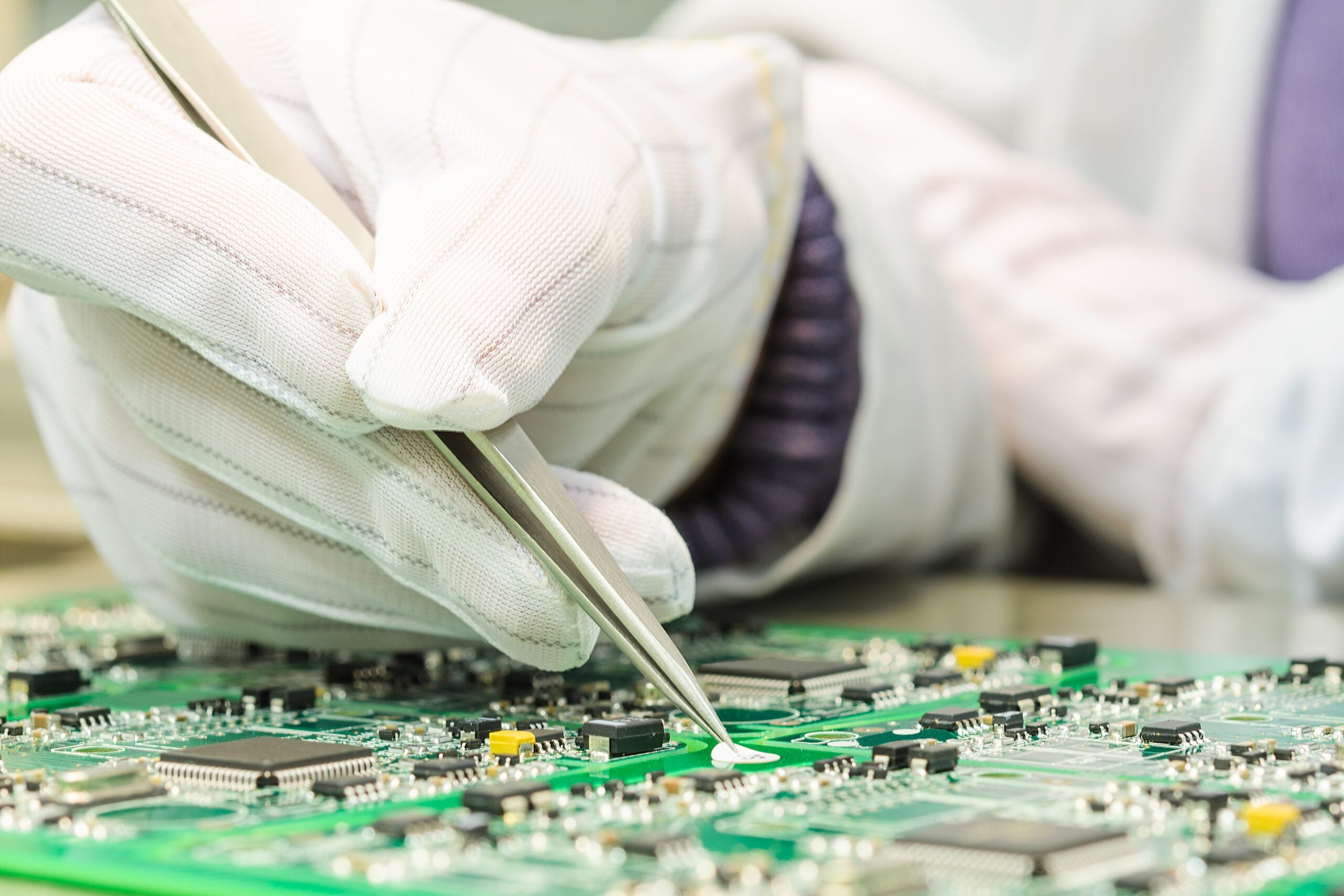

A recent study done by NASA proposed a simpler idea: enforcing IPC standards for the quality of electronics. The study determined the quality of components was directly related to how carefully a supplier required manufacturing to adhere to IPC standards. Higher component quality resulted in higher quality electronics. Requiring components to meet IPC standards would help manufacturers avoid a supplier creating less reliable components. The NASA study also included a wide variety of recommendations for how suppliers can improve their manufacturing processes to create components compliant with IPC standards.

Are Changes to the PCB and IC Supply Chain Viable?

Are Changes to the PCB and IC Supply Chain Viable?

Decentralizing the supply chain and implementing blockchain security mechanisms for electronic component hardware would likely have some significant logistical hurdles. Enforcing IPC standards might prove to be even more challenging. The IPC has recommended standards for electronic manufacturing for more than 60 years, and they are stringent and exacting for good reason. However, those strict compliance requirements appear daunting to many manufacturers, causing them to forgo IPC standards with some or all of their components. Some companies create their own standards based on IPC standards, but those proprietary standards are rarely more exacting than those of the IPC.

This doesn’t necessarily mean a significant change to PCB and IC supply chain management is impossible. Electronics societies—including IPC—have launched major education initiatives in the digital age. A new generation of electronics designers who have grown up with the internet are more likely to respect the importance of IPC standards.

Ultra Librarian provides PCB designers with essential tools for their PCB and IC supply chain management. Our partnerships with worldwide distributors ensure high-quality components for every project. Working with Ultra Librarian takes the guesswork out of preparing your next great device, and puts your ideas on the road to success. Register today for free!