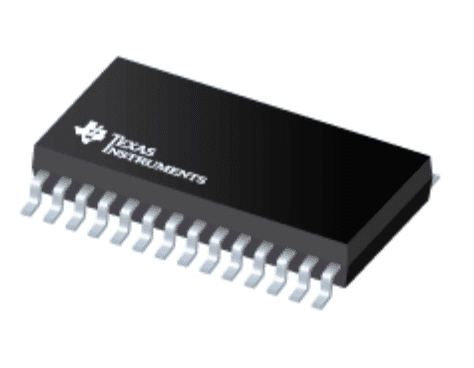

An MSP430 MCU from Texas Instruments

Texas Instruments has come a long way since the 486DX80-2 processor.

Embedded systems applications and components have always seemed to lag about 2 decades behind their conventional computing counterparts. However, embedded computing capabilities are finally catching up and enabling a range of unique products. Today, there are many powerful components on the market for embedded design and development, ranging from MCUs to FPGAs and specialty ASICs for a range of applications.

Embedded system design using MSP430 MCUs is a viable route for some new products that need a low-power processor with high GPIO count and standard digital interfaces. If you’re looking for processing power for your next embedded product, here’s what you can expect from the MSP430 line of MCUs from Texas Instruments and how you can incorporate an MSP430 into your new product.

Embedded Applications with MSP430 MCUs

As a low-power MCU with multiple operating modes, the MSP430 is useful in a range of embedded computing applications. Ideal applications for MSP430 MCUs range from industrial devices to automotive and IoT products with low compute requirements. The high GPIO count, analog interfaces, digital interfaces, and other integrated peripherals make the MSP430 useful in any embedded system that needs to send and receive data from multiple external devices.

Some important integrated peripherals and variant options for MSP430 MCUs include:

- ADC and DAC: These options can be configured from 8 to 12 bits with interleaving and grouping for synchronous update operations.

- Programmable Op-Amps: Can be internally configured as comparators, PGAs, differential amplifiers, instrumentation amplifiers, or standard high-gain op-amps.

- Timers: MSP430 devices include real-time hardware counter modules (32-bit), asynchronous 16-bit timers, and a watchdog timer.

- Multiple Temperature Ratings: Although the standard temperature range is from -40 °C to 85 °C, MSP430 variants are designated with multiple temperature ratings in the component’s MPN:

- HT: -55 °C to 150 °C

- EP: -55 °C to 125 °C

- T: -40 °C to 105 °C

- Q1: Automotive Q100 qualified from -40 °C to 105 °C

- 3V3 or 1V8 Supply: A low-voltage MSP430 that runs on 1.8 V supply voltage is available, although the temperature rating is limited from 0 °C to 50 °C.

- Digital Interfaces: MSP430 devices support I2C, SPI, UART (only on some components), and high GPIO count.

These integrated peripherals, interfaces, and component ratings are highly relevant for a range of embedded systems. ADCs, DACs, amplifiers, and various interfaces are essential for accessing a range of external devices and sensors that are needed for embedded products. To see a longer list of technical specifications, take a look at this article on MSP430 MCUs.

Programming and Flashing Your MSP430

Building firmware for embedded systems and getting code onto a device can sometimes seem like black magic. Thankfully, Texas Instruments has made this process easy with their proprietary Code Composer Studio (CCS), which includes dependencies and libraries needed to develop firmware for MSP430 devices. Firmware for MSP430 devices is written in C/C++. You can then use the integrated compiler in CCS to create a binary flash file for your MSP430 MCU.

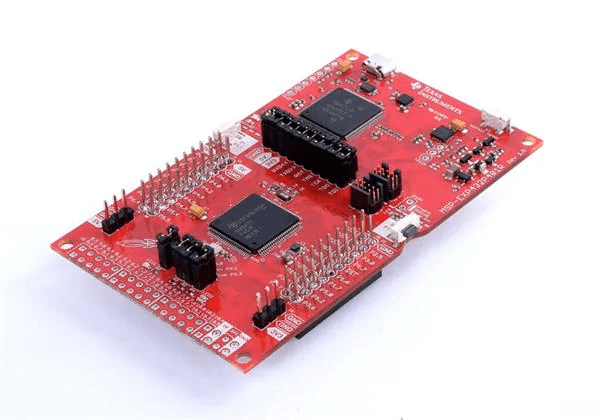

Once you’ve compiled your code down to a binary file, you can usually program the device using TI’s Uniflash application along with an XDS-110 debug interface (USB to UART). The MSP430 LaunchPad platform is TI’s proprietary development board for prototyping, testing firmware, and flashing MSP430 devices. When used for programming, the MSP430 LaunchPad provides the interface between your computer’s USB connection and the UART, JTAG, or gang programming connection on the MSP430.

The MSP430 LaunchPad is an essential platform for developing and debugging firmware, as well as flashing a new device.

The MSP430 LaunchPad is an essential platform for developing and debugging firmware, as well as flashing a new device.

Be sure to place a pin header on your board to provide access to the appropriate pins for flashing. For production programming or fab line programming, it’s best to use an SPI flash application to program MSP430 devices, an external Flash chip, or other MCUs/SoCs from Texas Instruments. You’ll also need to develop or find libraries for other components you include in your new product.

Other Components Needed for Embedded System Design Using MSP430s

Customized embedded systems need a range of components to interface with peripherals, connect to a wireless network or the internet, capture data from sensors, and other tasks involving data collection, processing, and transmission. Some components that might be needed to support an MSP430-based embedded application include:

- Voltage regulators (typically LDOs are most flexible)

- Passives for filtering, power decoupling, and supporting analog components

- Specialty ICs for interfacing with various sensors, particularly environmental sensors

- Antennas, baluns, and other RF components

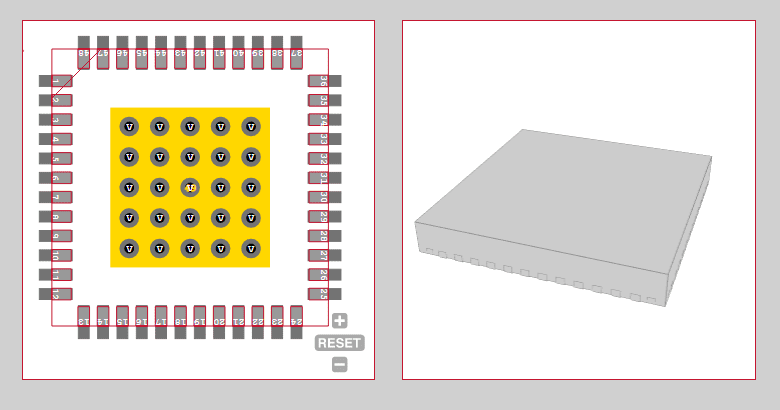

An alternative processor that provides the same flexibility as MSP430 MCUs with greater integration for use in smaller devices is the CC430 SoC. This component follows the same trend as Texas Instruments’ SimpleLink series of MCUs, where wireless capabilities are integrated into a standard MCU in a surface-mount package. The CC430 has the same specifications as other MSP430 MCUs but includes an RF transceiver for sub-1 GHz radio communication over digital FM protocols with 2-FSK, 4-FSK, GFSK, MSK, or OOK modulation.

The CC430 line of RF SoCs integrates a wireless transceiver with MSP430 core logic in a standard QFN package.

Embedded system design using MSP430 MCUs is much easier when you have access to verified component models and footprints directly from Texas Instruments. You can find ECAD data and component models for the MSP430 and other important components with the electronic parts search features of Ultra Librarian. You’ll have access to verified CAD models that can be imported into popular ECAD applications, and you can view sourcing information from worldwide distributors. Ultra Librarian helps by compiling all your sourcing and CAD information in one place, and all data is verified directly from component manufacturers.

Working with Ultra Librarian sets up your team for success to ensure any design is going through production and validation with accurate models and footprints to work from. Register today for free.