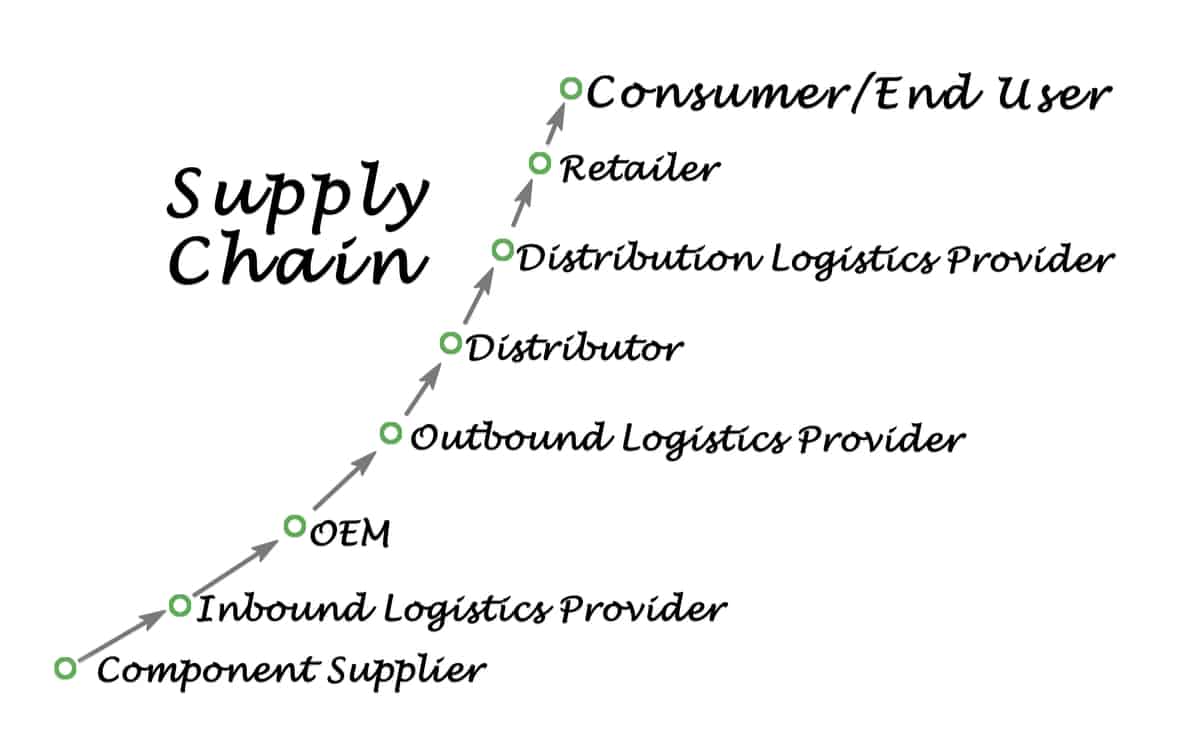

The electronic components supply chain

Whenever I have an order in and there is a delay, it causes me to cringe. However, as frustrating as hold-ups are, they are understandable—logistics can be complicated. Given all the moving parts of supply chains, it is a testament to the expert organization of supply chain managers that there are not more delivery problems.

After finally receiving your order, finding out you have been sent a counterfeit part is disappointing, especially if the component matriculates all the way through the supply chain and finds its way into an electronics product. The results of using a counterfeit part can include erroneous circuit behavior, underperformance, premature failure, or even physical harm. These issues illustrate the importance of having quality supply chain management practices in place.

Managing the supply chain effectively begins with component selection and sourcing, and efforts to avoid counterfeit electronic components should start there as well. In this article, we will discuss what counterfeit components are and how to avoid them to ensure product quality and security.

What Are Counterfeit Electronic Components?

To identify and avoid counterfeits, it is necessary to have a clear understanding of what we are trying to avoid.

There are multiple ways by which counterfeits are introduced into the electronics supply chain.As the definition above indicates, counterfeit components are not electronic parts manufactured with defects. Instead, the motivation behind creating these parts is to defraud the purchaser, often without any regard to the potential damage or injury that may result from using the components.

How do Counterfeit Components Enter the Supply Chain?

The PCBA development process can sometimes take months or years, depending on the complexity of the design. Therefore, a shortage can occur prior to board bring up that necessitates the replacement of a component. Similarly, if a component becomes obsolete after a product has been introduced into the market, a substitute has to be incorporated. These situations present an opportunity for the introduction of a counterfeit component.

At one time, bench repair and component replacement were even more commonplace than they are today, and due to the pursuit of lower costs, this was an ideal opportunity for the introduction of counterfeits. Today, these are relegated to specialized, custom components that make counterfeiting much more difficult.

Counterfeit components may become an issue at any time during the lifecycle of an electronic product or system, however, the most common entry point is during initial sourcing. Consequently, component selection in electronic system design is a critical element in identifying and avoiding counterfeits.

Avoiding Counterfeit Electronic Components in Your Design

If you opt for turnkey PCBA manufacturing, the brunt of the responsibility for avoiding counterfeit electronic components lies with your contract manufacturer (CM). Conversely, if you procure your own components, then you are able to visually inspect the parts for flaws and defects such as the ones listed below, which may indicate their authenticity should be questioned.

Here are some common counterfeit electronic component identifiers:

- Indent imperfections

- Label misspellings or inconsistent placement

- Easily removable markings

- Signs of wear or prior usage

- Inaccurate symbols or logos

More blatant or obvious divergence from the component footprint library, such as wrong package size or type, may not be an identifying factor for an attempt to defraud. Instead, this may simply be a vendor error in filling your order.

Even if you or your CM do successfully identify counterfeits before they are installed on your board, you will still likely have to endure time loss for development, missed delivery deadlines, and additional costs to acquire the needed components. Therefore, it is incumbent upon you to initiate good component supply chain management by employing measures to avoid the acquisition of counterfeit electronic components during design. This begins with understanding common risk factors.

| COUNTERFEIT ELECTRONIC COMPONENT RISK INDICATORS | ||

| INDICATION | LEVEL OF RISK | |

| Low | High | |

| Footprint-datasheet mismatch (For example, the footprint is wrong, but the part is labeled with the correct PN) | ✔ | |

| Non-standard package type | ✔ | |

| Unverifiable manufacturer | ✔ | |

| No datasheet | ✔ | |

| Footprint/symbol/3D model mismatch* | ✔ | |

* Incorrect dimensions/number of pins/location of reference indicators/MPN/labels are all issues that may indicate the component is counterfeit.

Knowing the common indicators of counterfeit components (and their associated risks) can be a great aid in the battle to identify and avoid fraudulent components and the development costs they entail. Employing these knowledge assets will help strengthen the first line of defense against counterfeit components entering the supply chain.

Your success in mitigating counterfeit electronic components is dependent on your source for CAD models for common components. Ultra Librarian works with manufacturers to verify library models and helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure any design is going through production and validation with accurate models and footprints to work from. Register today for free.